Of the 3 IMSBs that I have inspected this is the only one that I decided to replace. The 2 others I left in place after removing the seal to allow them to be lubricated by engine oil.

The bearing in the engine I am currently working on seemed OK when I removed the flange but I was worried by the fact that the “lubricant” that I found after pulling the seal looked like burned, hardened grease.

There is a picture in post #5 of this thread.

http://986forum.com/forums/performance-technical-chat/80969-going-through-my-original-engine.html#post644049

Despite this the bearing turned smoothly and showed no signs of play. Finally I decided to replace it with the same bearing that came in the engine from the factory. It is supplied by 123bearings.com (NSK BD20-17-A-DDUA17NX01-NSK) $57.79 US plus shipping.

I am relying on the videos done by Ben Burner to help me.

https://www.youtube.com/watch?v=lbM3c2V4scw&list=PLiya6G1pHhIYyzhlVzS_LwoIovrlv6_lv&index=7

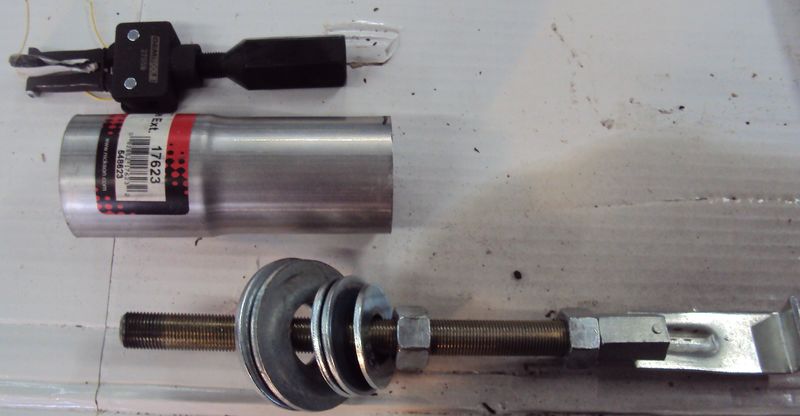

I bought the same puller that Ben used to get the old bearing out and cobbled up the bits and pieces necessary to extract the bearing with the puller, here are a couple of pictures.

The puller during the first (unsuccessful) attempt.

The final setup… I added some washers because during the first pull the 2 washers started to deform. I should have made the cylinder longer too, 6.5 in instead of 5.5 in (it is made from a piece of 2in ID exhaust pipe).

The problem that I ran into was that the arms of the puller flexed enough that claws of the puller passed through the center of the bearing. When I figured this out I fabricated a wedge that fits between the pullers arms, the thin edge of the wedge allows the puller to be inserted through the center of the bearing, then it is pulled into place so its thick end prevents the arms from deforming. This worked so I finally got the old bearing out.

Here is the wedge in the puller, insertion position and pulled back (using the yellow strings) to block the arms in place.

I would suggest perhaps starting with a puller like this.

https://www.amazon.ca/OTC-4581-Hammer-Bearing-Puller/dp/B0002SRH7Y

I have a question. The bearing has a thin spring clip that sits in the groove in the bearing and the groove in the block. I am wondering how to hold this clip in place while inserting the bearing. Will the chamfer on the block be enough to force it into place? Or should I tape it down in the bearing’s groove and count on the tape being stripped off as the bearing enters the block?