First a big THANK YOU! to the folks who provided the information to put me on the right track to finally (I think!) solve the SAI fault in my Box.

Since I did a bit of extracurricular studying on this one I thought I'd write it up and share the wealth. I read everything I could find on the SAI and even read through the Bosch "Gasoline-engine management Technical Instruction ME-Motronic engine management". Turns out Porsche doesn't design the engine management system, Bosch designs it for Porsche - other car companies too. Who knew?

Enough trivia, on to what Secondary Air Injection system (SAI) does. The SAI is designed primarily to control pollution at start up when the engine is cold, and the ambient temperature is below a predetermined limit. I think that limit is 70F but don't quote me on that. In cooler conditions, older carburetor equipped cars had a choke, which for you younger kids was a restriction plate kind of like a second throttle plate at the top of the carb that closed using a bimetal coil in the cold, and opened when the bimetal coil got hot. It's the same way those old timey round thermostats work. This makes the mixture rich enough to burn when the engine and air are cold. Turns out all engines need that rich mixture on a cold start including fuel injected engines. Fuel injected engines get that rich mixture by simply injecting more fuel. The problem is, that rich mixture does not burn completely and also has a lot of nasty polluting components in the combustion products due to the lack of air when it burns in the cylinder. Enter the SAI.

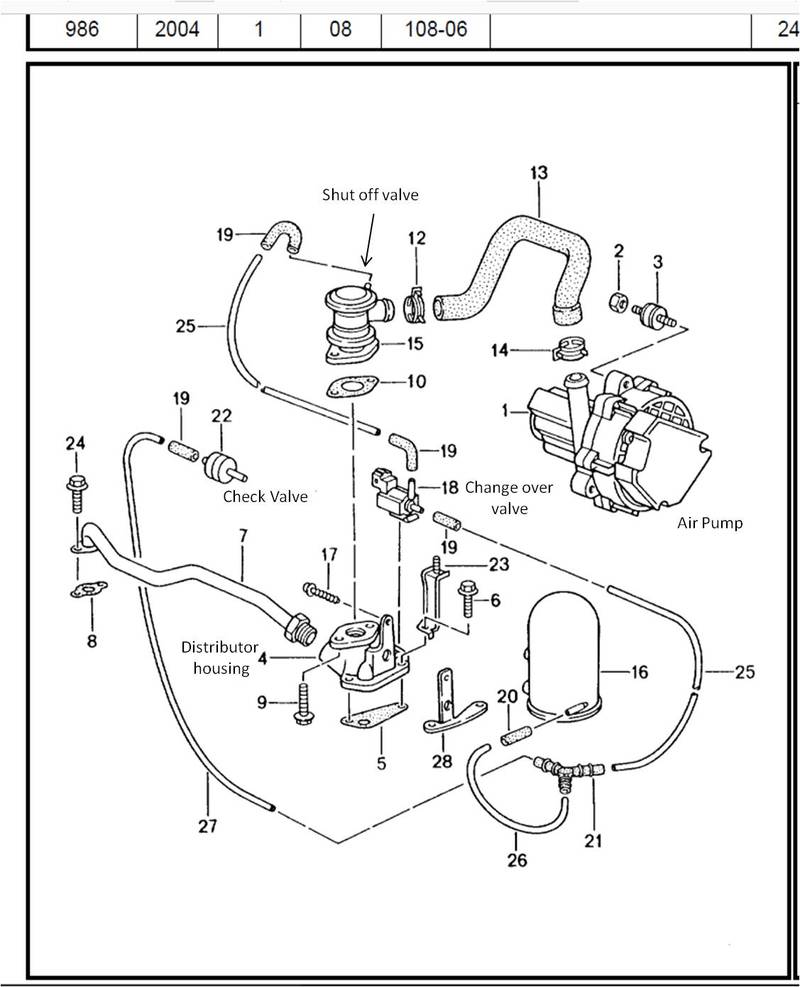

The SAI is made up of parts you can see, the pump, along with a system of hoses and valves to control the air when the pump is running. There is a part you can't see, which is comprised of holes running from the top of the head to the exhaust manifolds - those are the little holes and galleys you see if you remove your exhaust header. There is also a dedicated electrical system to run the pump and actuate the valves.

The SAI pumps air straight through the passages in the heads into the exhaust manifold where is meets up with all the nasty unburned fuel and pollutants to provides the oxygen they need to complete combustion. Then that "reburned" exhaust gas passes by the upstream O2 sensor in front of the catalytic converter, and then the downstream O2 sensor after the catalytic converter. One of the O2 sensors, I believe it is the downstream sensor (again, don't quote me) determines if the mixture is stoichiometric. Stoichiometric means the fuel and air mixture balance so all of the air is used and all of the fuel is used. The upshot is that most of the bad actor pollutants are combining with the SAI air to form less harmful compounds such as water and CO2. This also keeps nasty compounds and unburned fuel from fouling your cats. The mixture band where all this good stuff happens is very narrow, which means the SAI pretty tightly controlled by the O2 sensor which makes the whole system kind of finicky.

If you've read through all that, it suddenly makes sense why a vacuum leak would throw the system off. The mixture the car *thinks* it has is being leaned out by the vacuum leak, put that on top of the O2 sensor trying to control the SAI to a narrow band and at some point the system gives up and throws a CEL. It also explains why any deviation on the SAI side causes the whole scheme to crater. Hello CEL!

So how to go about diagnosing an SAI code when the code essentially says, "Something in your SAI is broken"? Start by not doing what I did. I hotwired the SAI pump and it ran, so far so good, I then decided I'd change out the "most likely" components and hope for the best. That was pretty stupid, I had to bust my knuckles and disassemble lots of stuff on the engine to spend money on and change parts that were perfectly good.

If I were to do it again this is what I would do in the following order:

Pull the black and white check valve - make sure it's working by blowing air though it both ways. if it doesn't stop airflow in one direction it's shot. Put it back in the way it came out - that is critical.

Check the intake manifold and hoses for vacuum leaks

Check the crank case for vacuum leaks

Check the 40 amp fuse in the trunk

Check the 40 amp relay in the trunk

Buzz out wires using schematic and ohm meter

Jumper the pump to make sure it runs

Only after the above would I move to other SAI components.

There are lots of ways on YouTube to check for vacuum leaks. I've used several methods and find the cheap cigar method to be the cheapest and quickest. You need a cheap cigar and about 3 feet of vacuum hose to inject smoke at your chosen fitting. I chose to use the 1/4 inch(ish) fitting between the AOS and throttle body and did the following

1) Set the engine to TDC. This closes all of the intake and exhaust valves to isolate the intake manifold and limit leaking into the cylinders

2) Remove the plastic intake pipe from the throttle body and slip a piece of 3 or 4 mil plastic sheet between the throttle body and intake tube. Snap the tube back on to seal the intake inlet.

3) Attach the vacuum tubing to the manifold fitting of your choice

4) Light a cheap cigar and blow the smoke into the intake manifold

5) for the SAI components and vacuum reservoir behind the SAI check valve I used a small vacuum pump showing no leak. One could remove the check valve and smoke check that if no vacuum pump is available

I was surprised how tight the manifold was. After about a lungful of air it was like trying to blow up a very difficult balloon and held pressure for about 2 minutes before leaking down. I did not see any smoke anywhere using a light.

Checking the crankcase was a similar exercise using the corner of a heavy duty trash bag with (white) electrical tape used to seal it and hold it in place. It yielded similar results

I've read that the fuse (yellow rectangle) in the trunk was on the firewall. Mine was in the left rear fender under the trunk liner and in perfect condition. The Relay / fuse holder slides out on rails.

The Relay is near the fuse. Mine is clearly fried. I removed it and tried to cycle it with the car battery and it is dead as a coffin nail. * We have a winner!* Woo Hoo!!!!!!

If I were still trouble shooting the next thing I would do is jumper the SAI pump to check operation. In my 2003 the red and black wire is positive.

The reason I would troubleshoot in the order given, is there little disassembly involved. If everything discussed so far passes, then it is time to start taking things apart, and that won't be easy due to lack of working room.

Had I not found the bad relay in the trunk I would proceed by removing the right hand side of the intake manifold and go from there. I have removed that with the engine in the car and it's not fun. When I replaced the SAI shutoff and change over valves I opted to remove the alternator and work under the manifold which was super tight but possible YMMV. Different years have different SAI components so this may not be possible on all models.

After dis-assembling to the SAI and before taking it apart, I would first pull a vacuum on the changeover valve and shut off valve (with a hand vacuum pump), then actuate the changeover valve with 12 volts while blowing into the air pump hose to see if the changeover / shutoff valves were working. If they are then it's time to smoke test the SAI circuit - hope those cigars are handy.

There is one more fault from my research apparently not uncommon on 993s, I've found one high mileage 986 having it. That is the SAI passages in the heads clogging with carbon. If everything else fails, and air is not going through the SAI through the exhaust when you smoke test it, drop the exhaust headers and use a long thin sharp wire to clean the carbon out of the SAI passages in the head.

Also I'd like to thank the folks at Pelican Parts who make this forum possible.