So yesterday a friend and I started the process of replacing the IMS and clutch. Things came apart without too much trouble, maybe 3 1/2 hours to get the tranny off.

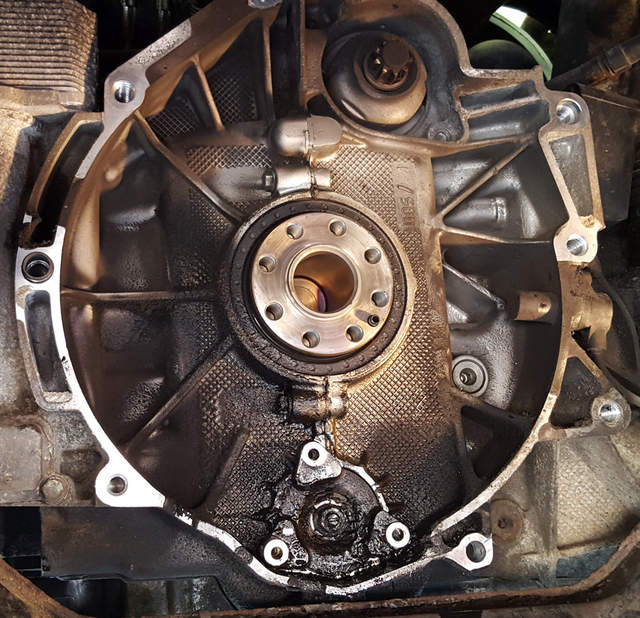

Looks like the RMS has been leaking. Got the cams positioned and locked along with the crank pulley. Then pulled the IMS bearing.

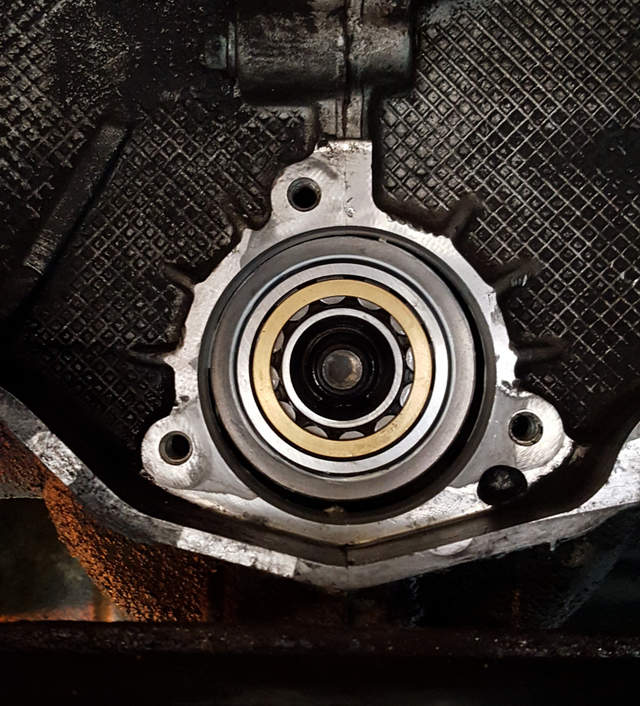

The IMS was in much better shape than I expected. It wobbled, but it would spin OK and the outer seal was still intact.

There was a lot of oil behind the bearing, and the IMS tube was full of metal particles. The back seal was also intact with a bunch of metal particles clinging to the edge. I pulled the seals off the bearing, it is intact but loose. It had been wearing for a long time. I am going to pull the races off today and inspect the bearings. If it wasn't the IMS bearing debris in my sump, then what was it.

It took quite a while top clean all the metal particles out of the IMS tube, but finally got it as I wanted and installed the new bearing. I went with the EPS solution. It took a little effort, but got the new bearing seated.

As I had heard described before, the IMS tube was not centered in the hole and was slightly up and to the left. But it easily centered when I installed the IMS cover. Installed the bolts and used thread sealer on the cover bolts and the center stud nut.

I will be replacing the RMS today. I am also going to replace the flywheel. It might be serviceable with a little polishing, it does seem to function properly per the spring back test. But, it has 87K on it, so it is really at end of life anyway and I don't want to tear out the tranny again soon.

New flywheel is on the way and hope to get it installed next week and finish everything up.