Quote:

Originally Posted by Smallblock454

Hi,

different forces: what i've meant is that if you reduce the car wheight by using a wireframe as chassis, you'll need a different spring and damping rate. Maybe strength, or energy is a better term for force.

Additionally the pushrod system will need a linkage to the wheel carrier. The wheel carrier was designed to take the main forces at the top where it connects to the damper/spring. If you use a double wishbone system, this won't be the problem. The problem can be the connection for the pushrod linkage at the wheel carrier.

The pushrod system has also the advantage to remove weight from the wheels (unsprung mass). That also means that you need to adjust dampening rates. The disadvantage is a little bit more friction because of the redirecting points.

Maybe you can adjust things with the gear ratio of the pushrod system.

Hope that makes sense to you. I'm not very good in translating technical terms from german to english.

|

I completely understand what your saying, As far as the coilovers I will be using, they will be custom ordered to the specifications that I need such as spring rates and damping rates. The dampeners with also be adjustable and can be sent back at anytime to be re valved if needed. That said I have no plan to order them any time soon. It wont be till the car is almost finished before I order them.

I have no problem making lower control arms as well if they are needed to support the additional load of the push rod setup. I also have another idea for the push rod setup that would allow me to keep the stock lower control arms.

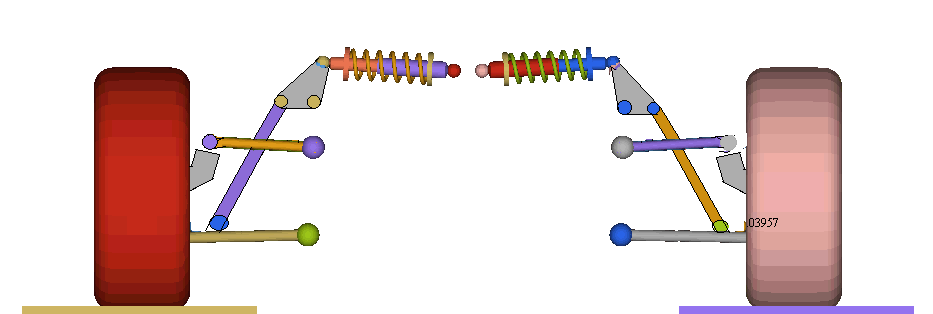

Here is a standard push rod setup

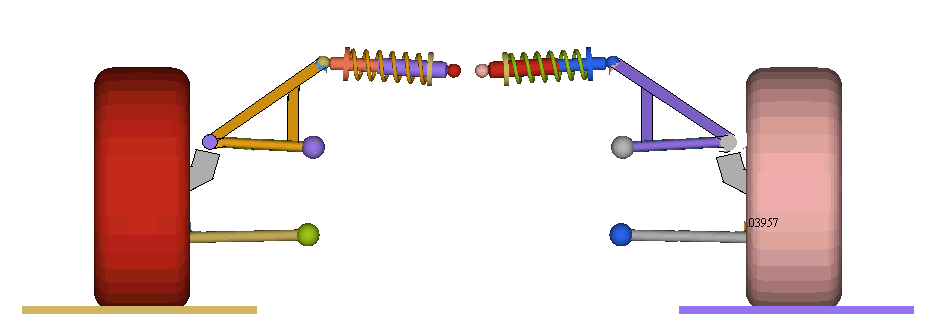

Here is an idea that would let me keep the stock lower control arms.

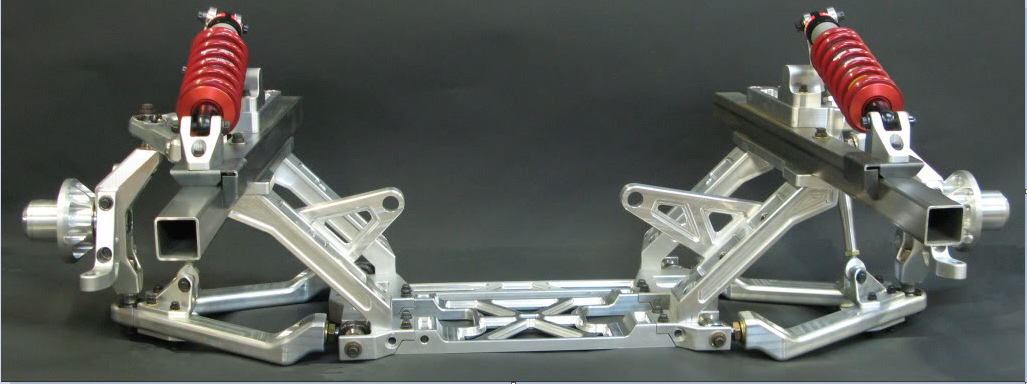

I'm also considering mounting the shock along the frame rails like this. It would save space and it should solve any interference issues I would come across.

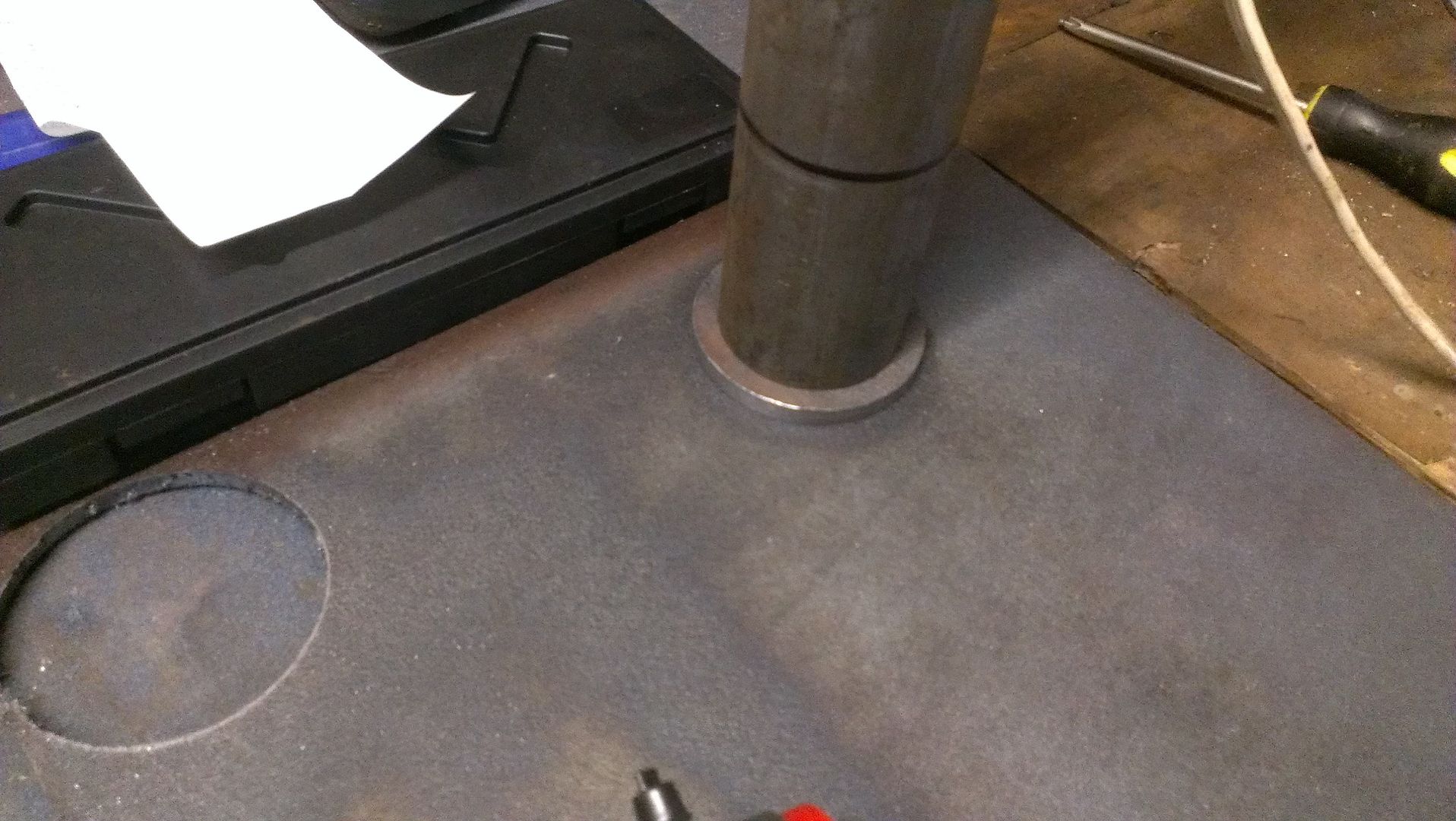

That said I have made a little progress.

I made a proto type adapter today