You'd think CNC means "press the button" and you go pick up your shinny part at the other end when finished! Yea... it is the case occasionally! But very often (99% of the time lol) you have to machine your part using multiple operations. Some may also require you to design and machine custom fixtures completely from scratch. Fixtures are hard to make and in most cases... it's artwork at its best.

In the case of this simple 2D part, we only have the front and back to machine so the fixture is pretty elementary. But still, it takes a few hours :/ Those fixtures (some call them jigs) needs to be precision built & assembled if you want the tolerance to live up to your designs. That particular fixture & part tolerance's are both +/- 0.1mm (human hair?)

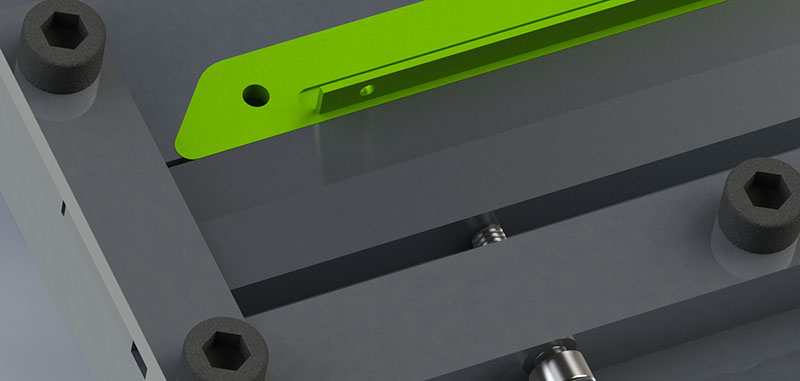

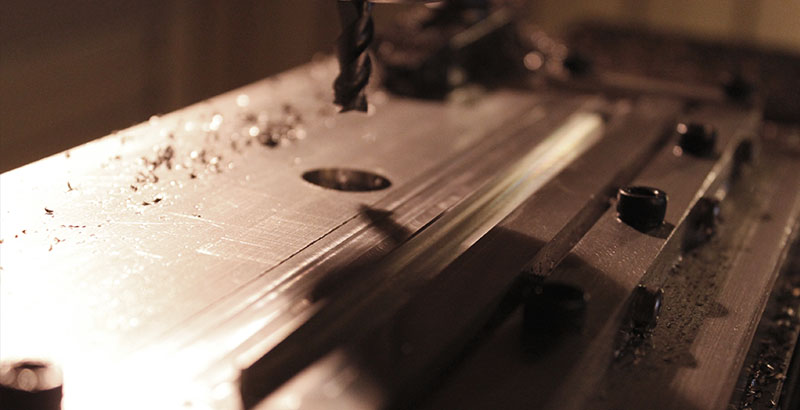

^ This is the fixture I've made to machine the back side of the blade. The part's profile was machined into the fixture at the exact same dimension as the top of the part. All you need to do is insert the part in that profile and squeeze it in there! That circular bore hole on top is where I set the machine reference relative to the part (digital probe finds the true center and pick up from there).

^ Those stainless steel hex screw is what secure (squeeze) the part in the fixture. Just needs a girly amount of clamping force for that part to stay snug and tight in there.

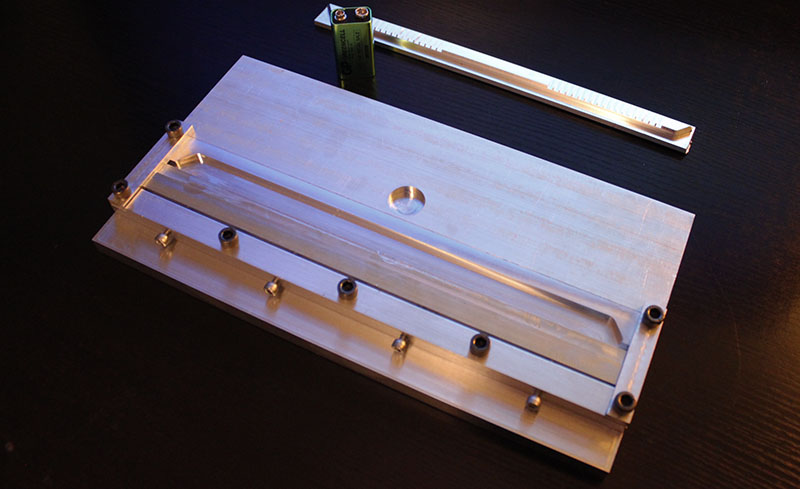

^ real life view of the fixture. No finishing, ruff on the outside but highly precise in the inside

Adv manufacturing lol

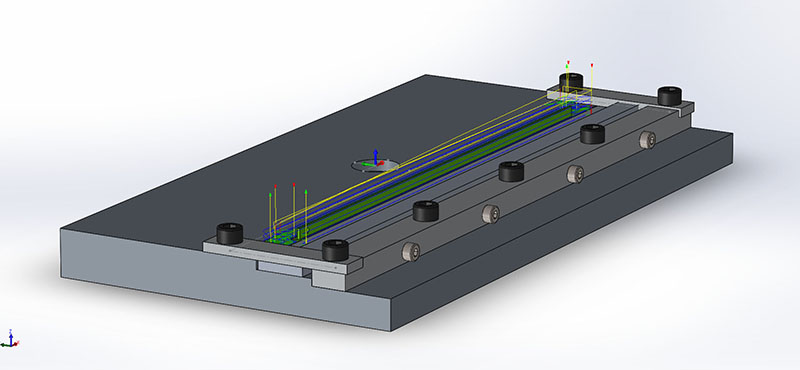

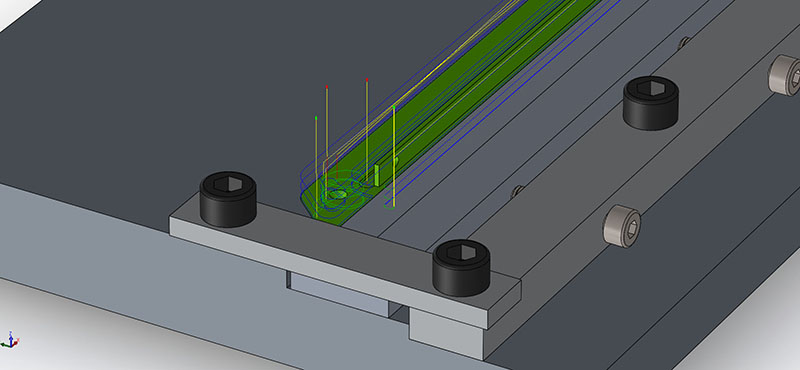

All left to do is the CAM work and GCODE coding for the bottom fact of the part. This is actually done from the CAD software directly with the part inside the fixture model. Once done... output that gcode to your controller, ref to the circular bore, and let it shred metal for 3.7min!

^ And you get this. High quality 100% aluminum machined part up to 0.1mm precision (the blade I mean, not the Chinese coca cola tin can!)

Doing projectors all of this weekend but I'll have time during the evenings of this coming week to anodize a few of those. I'll be starting work on the laser at about the same time so I'll update then!

Super LEDs for Porsche cars coming soon, stay tuned lol