Now I have to say that the TuneRS instructions are AMAZING!!! Both LN Engineering with their IMS Retrofit and TuneRS with their DOF say that you should have them professionally installed. But the TuneRS kit definitely seems more suited for the do-it-yourself home mechanic as it is really complete (they even include red thread locker) and their instructions are 65 pages full of detailed photos. Let that sink if for a second... The LN Engineering IMS Retrofit comes with one page of instructions, no photos. The TuneRS kit has 65 PAGES!!! Plus there is a You Tube install video. You can't go wrong...

A couple of points to help others though - they talk about finding TDC on the crank. Here's a picture showing the notch lined up at TDC.

Also, when removing the cam plugs, there is a hole in the middle. It's easiest to just puncture that hole (you're going to replace them any way) with a pick and pry them out... easy!

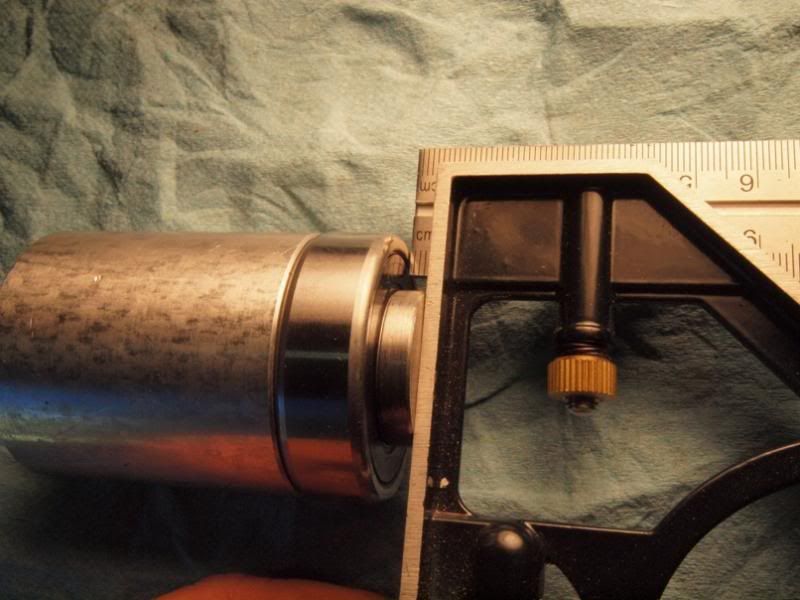

Another suggestion, when installing the bearing onto the center shaft, use a square, calipers, whatever you've got, to check and make sure it is seated perfectly square. Here is what I used to check all of the way around the bearing to make sure it was seated perfectly.

Here is the bearing I'm using - a SKF 6204 2RSH JEM bearing. Don't use an old production bearing. SKF updated their seals, so make sure it says RSH, which is the new seal that can withstand higher pressures. 2RSH means there are two seals, obviously I removed the one that will get the oil spray. JEM means that it is a C3 tolerance bearing. You want C3 as stock OEM was C3. All this means is that the tolerances of the bearing are set to account for thermal expansion. This bearing will get hot, so you need to have tolerances for thermal expansion.