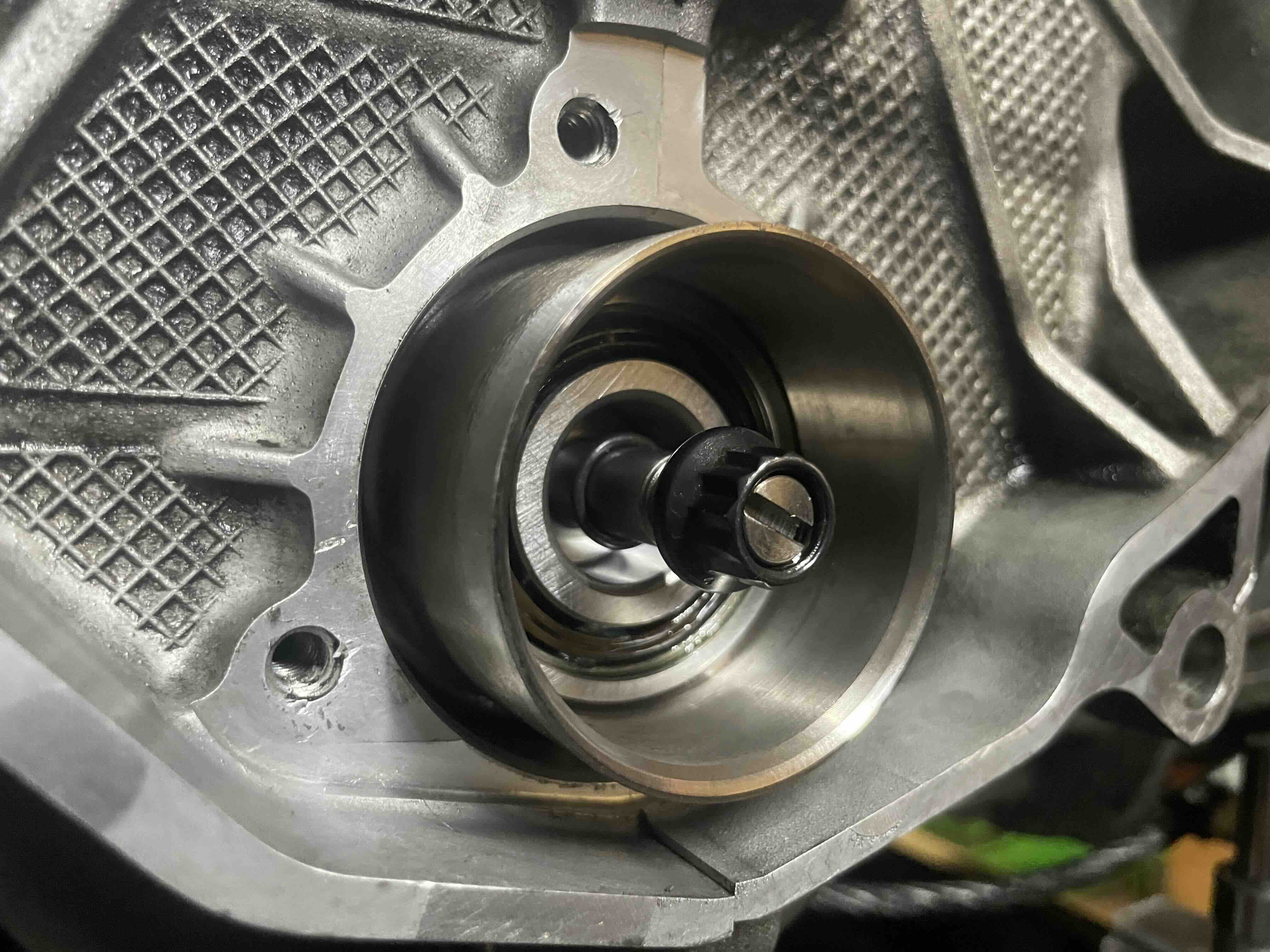

I am installing the LN Single Row Pro Retrofit kit using LN Engineering's M96 Faultless IMS Tool (

kit), and the THREADED ROD BROKE during installation

Now the new bearing is halfway in, but I'm concerned it wasn't aligned properly because obviously I applied too much torque to snap that threaded rod.

I have another rod from the IMS PRO Tool Kit 106-08.13, so my plan is use that rod to extract the bearing (and flipping the chamfer-side to face the bearing). Before I do anything, I'm praying for Jake to chime in because:

1. Why did the bearing stop inserting? I loosened the mount bolts as described to float the plate and ensure proper alignment.

2. Will the lock ring be compromised?

3. Where did I go wrong?