Little progress since last time. New timing chains ready for assembly.

Old vs. new chain tensioner.

Old vs new timing chain lined up. Not a super precise way to tell, but I can`t see any obvious sign of stretch.

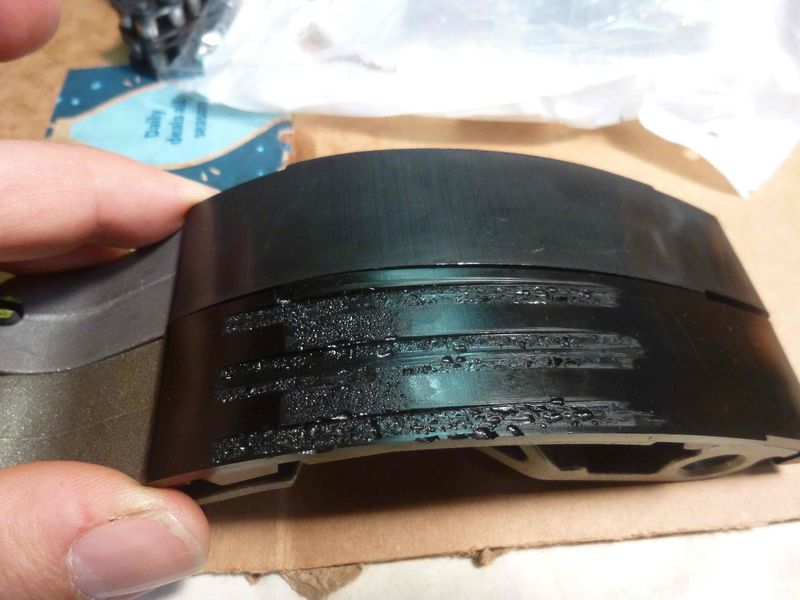

I put a small amount of sealant onto the gasket lips for the plastic oil scraper (?) to hold it in place during assembly. They put sealant there in the factory as well.

I spent about a good two hours closely looking at the pictures I made during disassembly to find out which rod goes with which piston, which cylinder and in what orientation. I marked everything, but that was 1.5 years ago and of course I couldn`t figure out what I meant by my markings back then

So I remarked everything and they are good to go.

Rod bolts, new vs old.

Rod bolts torqued to 20 Nm followed by an additional 90 degree turn. Hopefully that`s fine, as the respective line on the torque settings chart was a bit confusing.

IMS and chains joined again with the crankshaft. More tomorrow.