Quote:

Originally Posted by palindrome

Love watching the progress. What type of ultrasonic machine do you use?

|

Thanks @palindrome

I have a totally rubbish one as it went bang on Friday

waiting to hear back as to replacement hence why I don’t want to say the make

When it worked It worked well. It was a home unit, 30L, 800w ultrasonic 600w heat but it did run both 28hz and 40hz which helped. Cost about £300

Going forward I think I am going to go bigger and more powerful though still limited to single phase unfortunately. Cost goes up significantly once you get around 50L and higher, but you get what you pay for

Ultrasonics are awsm. I have some great videos showing a parts which were cleaned using carb cleaner, degreaser, vapour etc then within 20secs in the bath (temp around 50-60 degrees C) and the crud that comes from out is amazing. Especially from internal parts for example the oilways of the camshaft.

Its a little mesmerising, like a lava lamp. You are watching the part and nothing really happening then in a split second this wisps of oil, oxidisation, etc just start coming off the part.

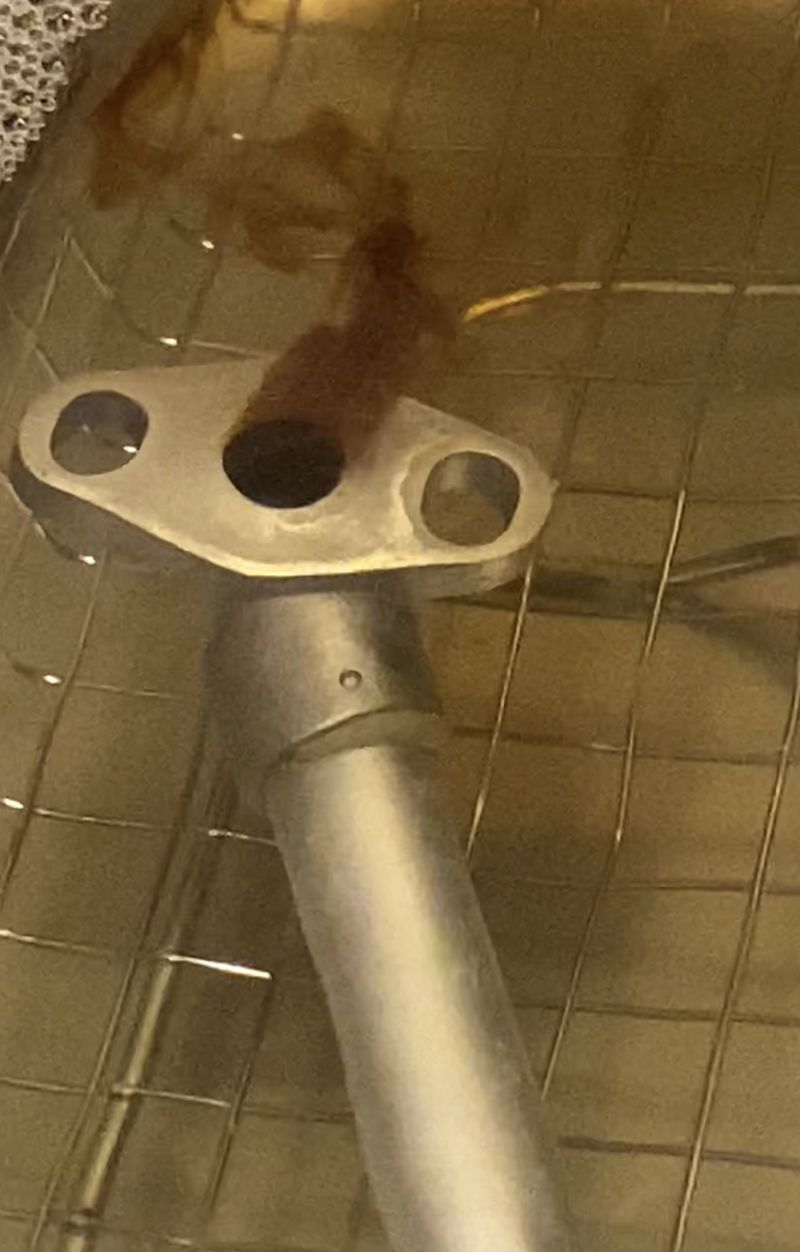

Below is a screenshot of one of the vids I had. The pipe was cleaned using carb cleaner and degreaser for about 10mins, outside looked like new, within 20secs the caked on oil inside started to cloud away. I put a snake cam into the first part and it was spotless

This is another screen shot of the IMS, lots of cleaning an polishing and the inside I cleaned using carb cleaner and a large pipe brush. The photo below shows the clouds of "stuff" coming from the inside. This dislodges some particulates which must have been caked on inside the ims.

Another great example of what is possible is the sump cover, vapoured, carb cleaner, pressure washer and again look at the impregnated crud coming off

My learning is to go as big and as powerful as possible. I now have two small units, which though are ok for small parts like nuts and bolts, are not really useful for otehr parts.

Also, learnt the hard way, the detergent or degreaser is important, had to replace some alloy parts which the detergent/degreaser, may in combo of the ultrasonic made them unusable. I now only use a sensitive metal detergent at the exact mix ration and I am getting some great results and ofcourse a rinse tank with anti flash added.