11-30-2021, 10:13 AM

11-30-2021, 10:13 AM

|

#1

|

|

2003 S, Arctic Silver, M6

Join Date: Oct 2014

Location: Winnipeg, MB, Canada

Posts: 1,346

|

It's called Dry Ice Blasting and has been around a long time in the metal working business. Here is a pretty good run down of what it is, how it works and what it is used for.

https://en.wikipedia.org/wiki/Dry-ice_blasting

The company I retired from is a primary supplier of the dry ice pellets to the industry.

|

|

|

11-30-2021, 11:47 AM

11-30-2021, 11:47 AM

|

#2

|

|

Registered User

Join Date: May 2021

Location: Stansted

Posts: 67

|

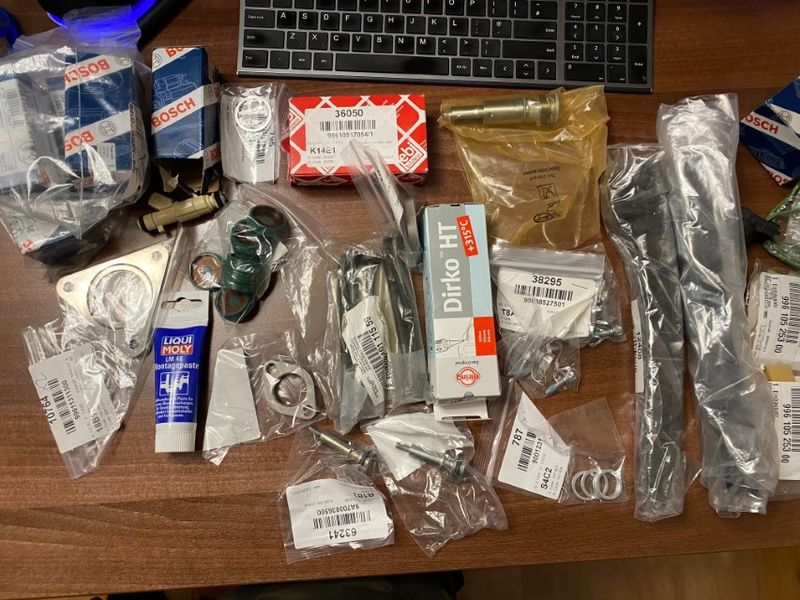

This is one of my favourite parts of any rebuild, no matter what is being rebuilt. When parts start to arrive. For me, it really is like have lots of birthdays

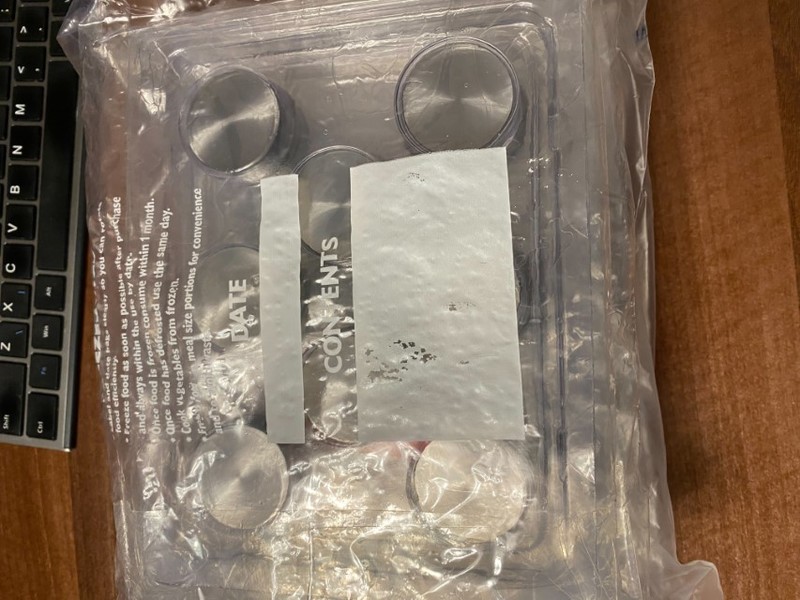

Recently, we have 24 brand new, shiny lifters/tappets packed in oil

A nice new oil separator with new gaskets

And lots of other parts inc, new injectors, seals, bolts, screws, knock sensors, chains, guides, tensioner, etc. Its only a small portion and loads more on the way, but I like to buy things slowly and especially when I can gab a bargain. As with the injectors and lifters which I paid less than half the normal price for the same part.

Hopefully the parts I need to start the bearing carrier rebuild will turn up soon

|

|

|

11-30-2021, 11:58 AM

11-30-2021, 11:58 AM

|

#3

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 842

|

Great thread, thanks for sharing! The two variocam units are completely different, they move the chain to the opposite side during the changover. After browsing many threads and taking apart mine for inspection my understanding is that mostly only one of them fails, the one that has the large greenish O-rings that are prone to disintegrate due to aging. I forgot which one it is, I have a thread on this topic somewhere. Theoretically if you remove that steel cover disc you can pull the piston and replace the faulty O-rings. It does not seem to be easy to do though, it requires machining, mill, lathe, etc. If you go down that route let us know how it worked out. When I was rebuilding mine I tested the variocam operation while spinning the engine on my bench and activating the solenoids, and both turned out good. I have a thread on this in show & tell.

Good pictures, keep them coming!

|

|

|

11-30-2021, 12:18 PM

11-30-2021, 12:18 PM

|

#4

|

|

Registered User

Join Date: May 2021

Location: Stansted

Posts: 67

|

Quote:

Originally Posted by Homeoboxter

Great thread, thanks for sharing! The two variocam units are completely different, they move the chain to the opposite side during the changover. After browsing many threads and taking apart mine for inspection my understanding is that mostly only one of them fails, the one that has the large greenish O-rings that are prone to disintegrate due to aging. I forgot which one it is, I have a thread on this topic somewhere. Theoretically if you remove that steel cover disc you can pull the piston and replace the faulty O-rings. It does not seem to be easy to do though, it requires machining, mill, lathe, etc. If you go down that route let us know how it worked out. When I was rebuilding mine I tested the variocam operation while spinning the engine on my bench and activating the solenoids, and both turned out good. I have a thread on this in show & tell.

Good pictures, keep them coming!  |

Awsm, thanks for sharing and I will definitely look up your thread.

I struggled to find any real description of the internals and also photos but lots of warnings and statements of “it can’t be done”, “non-serviceable” “cannot be refurbished” etc. I come from an engineering background and hearing that makes me think “really?” And makes me want to run an experiment to see why. Yes, once removed some parts cannot be reused, but with technology as it is today, such 3D-metal printing, CNC machines etc once we have a 3D model of the parts required then why cannot these non reusable parts be replaced? Maybe it’s cost, maybe it’s complexity, that’s the experiment I wish to run and I will share my observations not to encourage everyone not to replace with new Porsche parts but to share and document the observations for other

I have seen a European company that does produce reconditioned units so it must be possible

|

|

|

11-30-2021, 12:42 PM

11-30-2021, 12:42 PM

|

#5

|

|

Registered User

Join Date: May 2021

Location: Stansted

Posts: 67

|

Actually, quick question for our community, it feels that the spring in the main piston has a different compression rating between each side. I need to check but from memory bank 2 was far easier to compress than bank 1. The difference being bank 2 could be compressed by hand and bank 1 required far more effort.

Does anyone have any similar experience/knowledge or observations?

Thanks in advance

|

|

|

11-30-2021, 02:42 PM

11-30-2021, 02:42 PM

|

#6

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 842

|

Quote:

Originally Posted by OldManMo

Actually, quick question for our community, it feels that the spring in the main piston has a different compression rating between each side. I need to check but from memory bank 2 was far easier to compress than bank 1. The difference being bank 2 could be compressed by hand and bank 1 required far more effort.

Does anyone have any similar experience/knowledge or observations?

Thanks in advance

|

I didn`t notice that, it`s possible though. Perhaps oil got trapped in one of the units and gave you you the impression it`s harder to compress? Bt, check out this thread, has pics of the internals of both actuators: Boxster 986 particles in oil filter

|

|

|

12-01-2021, 01:05 AM

12-01-2021, 01:05 AM

|

#7

|

|

Registered User

Join Date: May 2021

Location: Stansted

Posts: 67

|

Quote:

Originally Posted by Homeoboxter

I didn`t notice that, it`s possible though. Perhaps oil got trapped in one of the units and gave you you the impression it`s harder to compress? Bt, check out this thread, has pics of the internals of both actuators: Boxster 986 particles in oil filter |

Hi Homeoboxter

Thanks, that is a very good point and I will check the deflection of each spring with a known load as its the only way to tell

Yes, it was that thread that encouraged me to look deeper into the units. Awesome information

|

|

|

12-05-2021, 03:09 AM

12-05-2021, 03:09 AM

|

#8

|

|

Registered User

Join Date: May 2021

Location: Stansted

Posts: 67

|

Sweet, all the parts bar one that I need to start the bearing carrier rebuild turned up today (yes on a Sunday  )

Another birthday day lol

|

|

|

| Thread Tools |

|

|

| Display Modes |

Hybrid Mode Hybrid Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 06:15 PM.

| |