The correct depth for the PTFE RMS is 13 mm, which can be a bear to obtain evenly without the correct tool, which you can rent from LN Engineering. This is a write up I did on another forum:

OK, pretty simple actually. If it is not out already, you need to pull the old seal. Normal way is to thread a small screw into the body of the seal and pull it out with pliers, being extremely careful to not let the screw scratch either the crank flange or the seal bore. Using a small lint free cloth and a bit of acetone, carefully wipe off any grease, oil, or residue left by the old seal. Both the bore and flange must be scrupulously clean, no fingerprints or any other materials should remain.

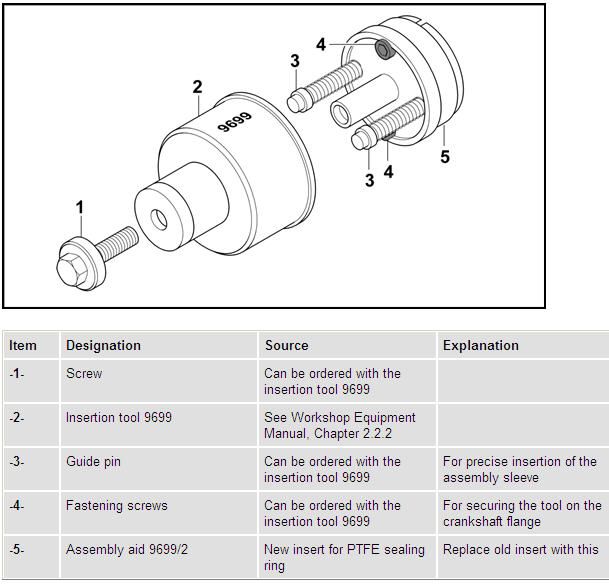

I've pulled down this diagram to help with the explanation:

Now slide the new seal over the assembly aid, being careful to not get fingerprints on the mating surfaces, clean nitrile gloves are the order of the day for this step. Attach the assembly aid (item #5 above) to the rear of the crank flange. I don't think the old flywheel bolts will do for this, my tool came with two bolts with small Torx style heads that fit inside the two openings. I sure you can find a metric Allan head bolt that would do the same job, but I think the old flywheel bolts have too large a shoulder on them which would get in the way. This assembly aid does not have to be overly tight, I just run it down with a 1/4 drive ratchet until they are snug. Now slide the insertion tool (#2 above) over the two guide pins and up against the seal, holding it there until you can get the large tightening screw started by hand and threaded down until it is holding the seal. Now, using a wrench or ratchet, carefully tighten the screw until the tool just bottoms against the assembly aid, which should set the seal at the prescribed 13MM insertion depth:

Now remove the large screw and insertion tool, then the assembly aid, and admire your new correctly installed PTFE seal.