08-14-2022, 04:26 PM

08-14-2022, 04:26 PM

|

#1

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Engine`s gone

I visit this forum because I enjoy reading stories about engine failures and I love to get an insight into the process of troubleshooting. I particularly find it interesting when a chain reaction of events leads to a catastrophe and turns the engine into a boat anchor in a fraction of a second, I guess that`s because of the dramatic effect and the irreversibility of the outcome. The story is somewhat less enjoyable though when the subject happens to be my car. Anyways, here it comes, I thought I share:

Yesterday on my way home the engine started making some weird noise, and stopped. I was able to pull into a parking lot with the engine off and I see this super thick white smoke coming from the exhaust. My first thought was, ok, it must be the AOS, but then I see coolant dripping from the overflow tube. Btw, the engine was not overheating, CEL was not on, there was absolutely nothing to indicate there`s something bad about to happen. I check the oil, looks fine, no signs of intermix. The oil level went up about two units though...

So I tow it home, pull the plugs assuming they are all oil-fouled. No oil, but one looks like this:

Oops. That`s not good.

So I peek into the cylinder with the borescope and find this disaster:

So, this is where I am at now, I`m not sure what happened, it looks like a D-chunk failure, the liner is clearly cracked, which explains why the oil level went up. This is the engine I rebuilt two years ago from scratch and there`s 12k miles in it.

I`m undecided whether I should rebuild it again using another core or I should just sell as a roller. Anyways, just wanted to share :ah:.

|

|

|

08-14-2022, 04:42 PM

08-14-2022, 04:42 PM

|

#2

|

|

Registered User

Join Date: Jun 2012

Location: Bedford, TX

Posts: 2,755

|

That is a real bummer. Thank you for sharing and good luck with the decision.

__________________

______________________________________________

2001 Boxster S Lapis Blue

TS Cat Bypass Pipes and exhaust

iPad Mini Dash Install

DEPO Tail Lights

|

|

|

08-14-2022, 09:25 PM

08-14-2022, 09:25 PM

|

#3

|

|

Registered User

Join Date: Jul 2019

Location: Finland

Posts: 354

|

oh-no! Sorry to see this happen.

Would be very interesting to know what caused this to happen and broke other stuff, maybe hard to tell for certain which let go first - D-chunk failure or something else

__________________

2001 996 C2 Manual

|

|

|

08-15-2022, 02:11 AM

08-15-2022, 02:11 AM

|

#4

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,526

|

Wow!

Is that the oil control ring besides the rest of the piston?

I think it's better to look for another engine. This won't be an easy fix, because everything has to be checked, measured, new sleeves, planed and so on. I think that's a little be above a DIY job to be honest.

Very sorry for the loss.

Regards from Germany,

Markus

__________________

My Porsche keyfob, instrument cluster and alarm ecu repair service: https://sportwagendoktor.de

|

|

|

08-15-2022, 07:53 AM

08-15-2022, 07:53 AM

|

#5

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Thanks, Guys. Yes, the rings are broken, but the sleeve is cracked in a D-shape too, and it`s impossible to tell at this point which happened first. My suspect is the aftermarket ringset, but a complete teardown might tell more once I get around doing it, if ever.

|

|

|

08-15-2022, 08:53 AM

08-15-2022, 08:53 AM

|

#6

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by Smallblock454

Wow!

Is that the oil control ring besides the rest of the piston?

I think it's better to look for another engine. This won't be an easy fix, because everything has to be checked, measured, new sleeves, planed and so on. I think that's a little be above a DIY job to be honest.

Very sorry for the loss.

Regards from Germany,

Markus

|

Yes, the engine is clearly damaged beyond repair, the broken casting should be welded up and resleeved which makes no sense as it`s way cheaper to get an intact core or short block and rebuild from there. Especially because this is the base 2.5 engine.

|

|

|

08-15-2022, 09:44 AM

08-15-2022, 09:44 AM

|

#7

|

|

Registered User

Join Date: May 2022

Location: NorCal

Posts: 39

|

What a bummer. What was involved in the original rebuild?

|

|

|

08-15-2022, 10:28 AM

08-15-2022, 10:28 AM

|

#8

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by casioqv

What a bummer. What was involved in the original rebuild?

|

Rings, bearings, valves on one bank, chains, etc., nothing major. You can look it up at the show&tell section, there`s a lengthy thread about it, if interested.

|

|

|

08-15-2022, 10:58 AM

08-15-2022, 10:58 AM

|

#9

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,655

|

What did you set the ring end gaps at on the new rings?

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

08-15-2022, 11:10 AM

08-15-2022, 11:10 AM

|

#10

|

|

Registered User

Join Date: Mar 2014

Location: Eastern NC

Posts: 701

|

I am sorry to hear that this happened to you.

__________________

"YouTube Certified in Various Specialties"

|

|

|

08-15-2022, 11:26 AM

08-15-2022, 11:26 AM

|

#11

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

Sorry to hear that especially after all the work of the rebuild.

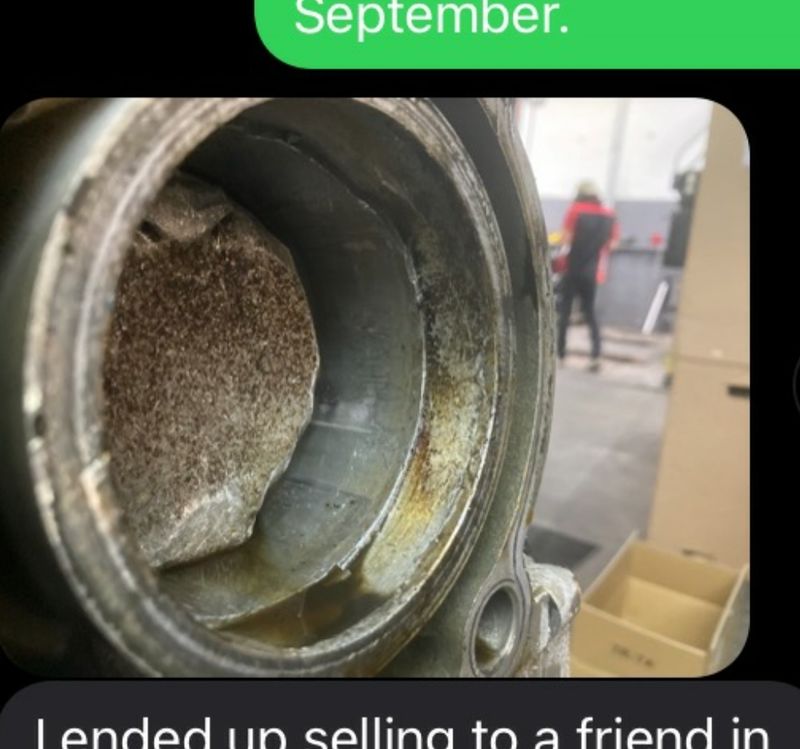

I had a friend with a very similar failure - looked like a slipped sleeve (#6) on a '99 with under 100k miles on it. Pic is from the guy that bought it afterward when he had the engine torn down:

I had sold him the car about a year earlier thinking that the engine was in great shape and that by the age and mileage it was past the chance of having the 'early Boxster' failure modes.

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

08-15-2022, 12:45 PM

08-15-2022, 12:45 PM

|

#12

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by JFP in PA

What did you set the ring end gaps at on the new rings?

|

I didn`t touch them. The two rings on top were ~ 0.4 and 0.8, similar to that of the originals, when I placed old and new on top of each other in the bore there was no difference. The side rails for the oil rings had smaller gaps than the original, but those looked worn and I didn`t adjust those either. But don`t you think if there had been a problem with the gapping then the engine wouldn`t have lasted this long but would have fallen apart earlier?

Another thing: the exhaust header was full of coolant, yesterday it was still dripping at the gaskets, indicating a lot of coolant got into the cylinder. Maybe the cylinder head cracked, the piston sucked coolant in causing hydrolock and the pressure cracked the cylinder wall? Just wondering if that`s possible

|

|

|

08-15-2022, 12:49 PM

08-15-2022, 12:49 PM

|

#13

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by 78F350

Sorry to hear that especially after all the work of the rebuild.

I had a friend with a very similar failure - looked like a slipped sleeve (#6) on a '99 with under 100k miles on it. Pic is from the guy that bought it afterward when he had the engine torn down:

I had sold him the car about a year earlier thinking that the engine was in great shape and that by the age and mileage it was past the chance of having the 'early Boxster' failure modes.

|

Wow, that`s crazy. Looks like the piston got seized and pulled the sleeve. I`ve never seen such a failure. These engines are truly amazing with all these unique failure modes

|

|

|

08-15-2022, 01:17 PM

08-15-2022, 01:17 PM

|

#14

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,655

|

Quote:

Originally Posted by Homeoboxter

I didn`t touch them. The two rings on top were ~ 0.4 and 0.8, similar to that of the originals, when I placed old and new on top of each other in the bore there was no difference. The side rails for the oil rings had smaller gaps than the original, but those looked worn and I didn`t adjust those either. But don`t you think if there had been a problem with the gapping then the engine wouldn`t have lasted this long but would have fallen apart earlier?

Another thing: the exhaust header was full of coolant, yesterday it was still dripping at the gaskets, indicating a lot of coolant got into the cylinder. Maybe the cylinder head cracked, the piston sucked coolant in causing hydrolock and the pressure cracked the cylinder wall? Just wondering if that`s possible  |

0.4 - 0.8 what? MM, inches?

No, improperly gapped rings can fail at different times and in different ways, depending upon which way they were off. Engine failures are a cascading event, the only way to try and figure it out is to pull it apart and look at each failed part. And yes, and casting failure can lead to hydro locking and blown out cylinder walls

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

08-15-2022, 01:57 PM

08-15-2022, 01:57 PM

|

#15

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by JFP in PA

0.4 - 0.8 what? MM, inches?

No, improperly gapped rings can fail at different times and in different ways, depending upon which way they were off. Engine failures are a cascading event, the only way to try and figure it out is to pull it apart and look at each failed part. And yes, and casting failure can lead to hydro locking and blown out cylinder walls

|

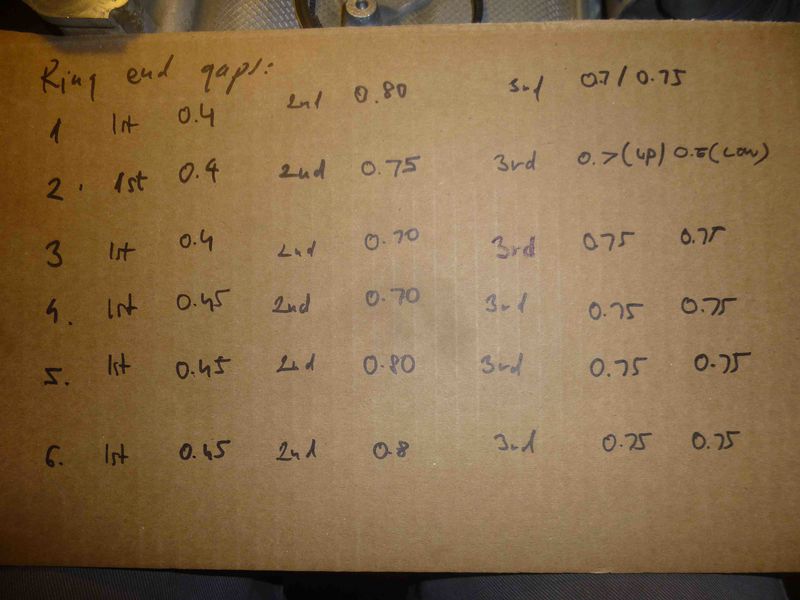

MM.

These were the gap values that I measured in the original engine, the new ring gaps were very close:

Yes, I`m curious to see what went wrong.

|

|

|

08-15-2022, 02:33 PM

08-15-2022, 02:33 PM

|

#16

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,655

|

OK, lets start with the top ring. Based upon accepted standards for ring end gaps, based upon bore diameters: Most piston ring manufacturers recommend a minimum end gap of .004 inches times the bore diameter for the top piston compression ring. So for a 4 inch bore, the standard end gap would be .016 inches. As you have an 85.5 mm, or 3.366 inches. Using the suggested rule of thumb, which would work out at 0.004 X 3.366 = 0.013 inches, or 0.33 mm. So that ring gap is way too wide.

Mahle, the makers of these pistons have published ring end gap guidelines for the 2.5 and 2.7L M96 engines:

Mahle

Top ring-0,15...0,35mm....006"-.014"

2nd ring-0,60-0,80mm....024"-.032"

oil control-0,50-0,75mm...020"-.030"

Again, your gaps appear excessive. Overly large ring end gaps can cause a myriad of issues, from compression loss to oil consumption, and most importantly, excessive piston rock in the bore, which can result in ring land (the piston metal that separates the rings from each other) failures.

When a piece of ring land material breaks loose, it can get wedged between the piston and cylinder wall, stressing both. I would not be surprised to find that if you pulled the pistons out, you would find multiple ring land failures. I also noticed from your assembly photos that there were significant gaps between the rings and the cylinder walls, indicating oval cylinder liners, which would also exacerbate that piston rocking problem even more.

Lawyers often like to say that, "the devil is in the details". That is also very true for engine assembly.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 08-15-2022 at 02:46 PM.

|

|

|

08-15-2022, 02:51 PM

08-15-2022, 02:51 PM

|

#17

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,655

|

This is what ring land failure looks like:

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

08-16-2022, 06:13 AM

08-16-2022, 06:13 AM

|

#18

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by JFP in PA

OK, lets start with the top ring. Based upon accepted standards for ring end gaps, based upon bore diameters: Most piston ring manufacturers recommend a minimum end gap of .004 inches times the bore diameter for the top piston compression ring. So for a 4 inch bore, the standard end gap would be .016 inches. As you have an 85.5 mm, or 3.366 inches. Using the suggested rule of thumb, which would work out at 0.004 X 3.366 = 0.013 inches, or 0.33 mm. So that ring gap is way too wide.

Mahle, the makers of these pistons have published ring end gap guidelines for the 2.5 and 2.7L M96 engines:

Mahle

Top ring-0,15...0,35mm....006"-.014"

2nd ring-0,60-0,80mm....024"-.032"

oil control-0,50-0,75mm...020"-.030"

Again, your gaps appear excessive. Overly large ring end gaps can cause a myriad of issues, from compression loss to oil consumption, and most importantly, excessive piston rock in the bore, which can result in ring land (the piston metal that separates the rings from each other) failures.

When a piece of ring land material breaks loose, it can get wedged between the piston and cylinder wall, stressing both. I would not be surprised to find that if you pulled the pistons out, you would find multiple ring land failures. I also noticed from your assembly photos that there were significant gaps between the rings and the cylinder walls, indicating oval cylinder liners, which would also exacerbate that piston rocking problem even more.

Lawyers often like to say that, "the devil is in the details". That is also very true for engine assembly. |

Thanks for looking into this! We should have had this conversation 2 years ago.. As I can recall I could not find specifications for the ring end gaps so I just went with the new rings assuming they should be ok. Based on the values you posted from Mahle the old worn rings were within or just out of spec, the new ones had similar or slightly smaller end gaps. The picture shows an old side rail from the oil ring, it came out stuck and probably deformed from the ring groove where it was stuck in gunk. With the new side rail there was no gap between the rail and the cylinder wall. Also, the car was running strong, no smoke, no excessive oil consumption. I didn`t find metallic particles inside the oil filter at the last oil change.

I`ll see what`s inside, it will be a great learning experience.

|

|

|

08-17-2022, 06:39 PM

08-17-2022, 06:39 PM

|

#19

|

|

Registered User

Join Date: Dec 2009

Location: Orange County, CA

Posts: 2,007

|

Hello Homeoboxter, bust just ran into this engine (not affiliated), but it seems that could be a great deal for the price, if it works out you could have with a nice powerplant for your Boxter :-)

https://rennlist.com/forums/market/1313957

|

|

|

08-17-2022, 09:04 PM

08-17-2022, 09:04 PM

|

#20

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by Gilles

Hello Homeoboxter, bust just ran into this engine (not affiliated), but it seems that could be a great deal for the price, if it works out you could have with a nice powerplant for your Boxter :-)

https://rennlist.com/forums/market/1313957 |

Thanks! Wow, indeed sounds like a great deal. However, I would have to replace or reprogram the DME for this and modify a number of things, and probably it wouldn`t pass the smog test easily. Not sure if it`s worth the hassle... It would be great though  2,500 mile 2006 Cayman S engine with low leak down test numbers.

2,500 mile 2006 Cayman S engine with low leak down test numbers.

Why would one do a leak down test on a 2500 mile engine? It`s basically brand new. And why would one swap an engine after 2500 miles? Just wondering..

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 07:09 AM.

| |