05-31-2021, 03:08 PM

05-31-2021, 03:08 PM

|

#1

|

|

Registered User

Join Date: Oct 2019

Location: California

Posts: 35

|

Exhaust manifold studs pros and con questions....

I just got done drilling out 4 broken studs on bank 1 which snapped on me. Was curious has anyone done a stud conversion on these? Or would you recommend factory or hardware store grade with anti seize?

|

|

|

05-31-2021, 03:22 PM

05-31-2021, 03:22 PM

|

#2

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by Johnny5

I just got done drilling out 4 broken studs on bank 1 which snapped on me. Was curious has anyone done a stud conversion on these? Or would you recommend factory or hardware store grade with anti seize?

|

I would go studs with brass nuts.

The only issue I have ever had with that setup is that sometimes the brass nuts loosen up.

But checking them once or twice a year is the answer to that issue.

Studs and nuts on exhaust is way better in my opinion then bolts.

If you use studs with brass nuts even if the studs rust the softer brass nut releases without to much problem.

|

|

|

05-31-2021, 03:33 PM

05-31-2021, 03:33 PM

|

#3

|

|

Registered User

Join Date: Oct 2019

Location: California

Posts: 35

|

Quote:

Originally Posted by blue62

I would go studs with brass nuts.

The only issue I have ever had with that setup is that sometimes the brass nuts loosen up.

But checking them once or twice a year is the answer to that issue.

Studs and nuts on exhaust is way better in my opinion then bolts.

If you use studs with brass nuts even if the studs rust the softer brass nut releases without to much problem.  |

Thanks for the response. What material studs? Stainless?

Also where’s a good place to source these?

|

|

|

05-31-2021, 04:02 PM

05-31-2021, 04:02 PM

|

#4

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by Johnny5

Thanks for the response. What material studs? Stainless?

Also where’s a good place to source these?

|

Lots of people say stainless for exhaust but that is a mistake in my opinion.

Stainless is very hard if you brake one off ( and it does happen with stainless)they are hell to drill out.

So I use a soft material such as grade 4. Then If I have to drill it out it drills easy.

I have found common exhaust studs ( the type that are threaded on both ends) at Ace Hardware.

You will have to check to see if they are Metric so they fix the Porsche.

Napa auto parts. would be another source.

Brass nuts can be a little harder to find but Napa should be able to help.

|

|

|

05-31-2021, 04:16 PM

05-31-2021, 04:16 PM

|

#5

|

|

Registered User

Join Date: Sep 2016

Location: Central Ohio

Posts: 415

|

Quote:

Originally Posted by Johnny5

Thanks for the response. What material studs? Stainless?

Also where’s a good place to source these?

|

No reason to over-think this. I simply went to my local hardware store, bought a dozen M8 ( ... I think, thread size from memory) plain old carbon steel long full thread bolts, and Dremel'd their heads off so to give me full threaded studs.

I then used SS nuts with high temp anti-seize on the threads.

Simple.

__________________

2000 Ocean Blue Boxster S

1980 Ferrari 308 GTSi

2019 Alfa Romeo Giulia Ti Sport AWD

Last edited by Dave80GTSi; 05-31-2021 at 04:19 PM.

|

|

|

05-31-2021, 05:51 PM

05-31-2021, 05:51 PM

|

#6

|

|

Registered User

Join Date: Oct 2019

Location: California

Posts: 35

|

Quote:

Originally Posted by blue62

Lots of people say stainless for exhaust but that is a mistake in my opinion.

Stainless is very hard if you brake one off ( and it does happen with stainless)they are hell to drill out.

So I use a soft material such as grade 4. Then If I have to drill it out it drills easy.

I have found common exhaust studs ( the type that are threaded on both ends) at Ace Hardware.

You will have to check to see if they are Metric so they fix the Porsche.

Napa auto parts. would be another source.

Brass nuts can be a little harder to find but Napa should be able to help.

|

Thank you. Will visit Ace tomorrow as they are closing early today.

|

|

|

05-31-2021, 05:55 PM

05-31-2021, 05:55 PM

|

#7

|

|

Registered User

Join Date: Oct 2019

Location: California

Posts: 35

|

Quote:

Originally Posted by Dave80GTSi

No reason to over-think this. I simply went to my local hardware store, bought a dozen M8 ( ... I think, thread size from memory) plain old carbon steel long full thread bolts, and Dremel'd their heads off so to give me full threaded studs.

I then used SS nuts with high temp anti-seize on the threads.

Simple.

|

Looks good. Reason why I wanted to ask is that some forums had a big debate on studs vs factory so was curious. I have studs with copper nuts on my M3 and they’ve been great.

I do like that option as well if I can’t find the double end exhaust studs to just go with full threaded and cut the heads and retap the end. Will see what I can find tomorrow.

Thanks for the reply and suggestion

|

|

|

05-31-2021, 06:20 PM

05-31-2021, 06:20 PM

|

#8

|

|

Registered User

Join Date: Oct 2020

Location: KY

Posts: 1,213

|

As blue said, go with copper nuts (not stainless). The reason for this is that same composition metals will undergo "cold welding" under high temperature and pressure, whereas dissimilar metals (i.e. steel and copper) will not.

It's a neat process. It happens in a total vacuum. Touch two steel rods together and they become one. Here, the heat and pressure just serve to drive it all the oxygen molecules out from between the iron molecules.

Knowledge is power!

Btw, the downside of using threaded rod instead of actual studs is that the studs have a hex head cut into the end, whereas the rods will require double nuts to torque and loosen.

I used m8 x 50 mm studs for a Ford V8, cost $15 for the dry on Amazon.

Sent from my POCOPHONE F1 using Tapatalk

__________________

2000 Box Base, Renegade Stage 1 performance mods complete, more to come

When the owners manual says that the laws of physics can't be broken by this car, I took it as a challenge...

Last edited by ike84; 05-31-2021 at 06:24 PM.

|

|

|

05-31-2021, 06:42 PM

05-31-2021, 06:42 PM

|

#9

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by ike84

As blue said, go with copper nuts (not stainless). The reason for this is that same composition metals will undergo "cold welding" under high temperature and pressure, whereas dissimilar metals (i.e. steel and copper) will not.

It's a neat process. It happens in a total vacuum. Touch two steel rods together and they become one. Here, the heat and pressure just serve to drive it all the oxygen molecules out from between the iron molecules.

Knowledge is power!

Btw, the downside of using threaded rod instead of actual studs is that the studs have a hex head cut into the end, whereas the rods will require double nuts to torque and loosen.

I used m8 x 50 mm studs for a Ford V8, cost $15 for the dry on Amazon.

Sent from my POCOPHONE F1 using Tapatalk

|

Ike,

Exactly, I don't like stainless or higher grade metal in any exhaust fastener.

If for some reason you have to drill, cut, whatever to remove it, softer is better.

Copper or brass nuts will not freeze on rusted steel. No galvanic corrosion with the brass or copper.

A clamp or band or pipe that is stainless is great just not the fasteners.

|

|

|

06-01-2021, 12:08 AM

06-01-2021, 12:08 AM

|

#10

|

|

Registered User

Join Date: Oct 2019

Location: California

Posts: 35

|

Quote:

Originally Posted by ike84

As blue said, go with copper nuts (not stainless). The reason for this is that same composition metals will undergo "cold welding" under high temperature and pressure, whereas dissimilar metals (i.e. steel and copper) will not.

It's a neat process. It happens in a total vacuum. Touch two steel rods together and they become one. Here, the heat and pressure just serve to drive it all the oxygen molecules out from between the iron molecules.

Knowledge is power!

Btw, the downside of using threaded rod instead of actual studs is that the studs have a hex head cut into the end, whereas the rods will require double nuts to torque and loosen.

I used m8 x 50 mm studs for a Ford V8, cost $15 for the dry on Amazon.

Sent from my POCOPHONE F1 using Tapatalk

|

Thank you for the response and additional info. So you happen to have a link to the set you bought with the hex at the end?

|

|

|

06-01-2021, 06:39 AM

06-01-2021, 06:39 AM

|

#11

|

|

Registered User

Join Date: Sep 2016

Location: Central Ohio

Posts: 415

|

I've used SS nuts on carbon steel studs over the past 4-1/2 decades of car exhaust wrenching, and have yet to encounter a single example of one seizing to the other.

As I said earlier ... Don't overthink this.

DM

__________________

2000 Ocean Blue Boxster S

1980 Ferrari 308 GTSi

2019 Alfa Romeo Giulia Ti Sport AWD

|

|

|

06-01-2021, 07:03 AM

06-01-2021, 07:03 AM

|

#12

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by Dave80GTSi

I've used SS nuts on carbon steel studs over the past 4-1/2 decades of car exhaust wrenching, and have yet to encounter a single example of one seizing to the other.

As I said earlier ... Don't overthink this.

DM

|

Yes and in the same 45-50 year period I have encountered the problem more then once.

I don't consider doing something different as overthinking.

Just using "my" experiences as a guide.

|

|

|

06-01-2021, 10:07 AM

06-01-2021, 10:07 AM

|

#13

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by blue62

Ike,

Exactly, I don't like stainless or higher grade metal in any exhaust fastener.

If for some reason you have to drill, cut, whatever to remove it, softer is better.

Copper or brass nuts will not freeze on rusted steel. No galvanic corrosion with the brass or copper.

A clamp or band or pipe that is stainless is great just not the fasteners.

|

There are several different grades of Stainless steel.

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

06-01-2021, 10:13 AM

06-01-2021, 10:13 AM

|

#14

|

|

Registered User

Join Date: Sep 2006

Location: Omaha

Posts: 2,959

|

Sorry I'm late to the party, but I wanted to add for historical reference. Sounds like you're going studs. I wanted to discuss bolts.

When I changed the driver's exhaust manifold on my CSS, I went to the hardware store and bought some M8 bolts. Turns out the heads were 12mm while the heads on the factory bolts were 13s. Thinking long term, I decided to order a set of factory bolts since I figured the 13mm head would be easier to loosen in the future vs the 12s. Plus the head on the factory bolt was meatier. Just made sense to go with factory.

Now back to stud discussion...

__________________

GPRPCA Chief Driving Instructor

2008 Boxster S Limited Edition #005

2008 Cayman S Sport - Signal Green

1989 928 S4 5 spd - black

|

|

|

06-01-2021, 11:45 PM

06-01-2021, 11:45 PM

|

#15

|

|

Registered User

Join Date: Oct 2019

Location: California

Posts: 35

|

Quote:

Originally Posted by husker boxster

Sorry I'm late to the party, but I wanted to add for historical reference. Sounds like you're going studs. I wanted to discuss bolts.

When I changed the driver's exhaust manifold on my CSS, I went to the hardware store and bought some M8 bolts. Turns out the heads were 12mm while the heads on the factory bolts were 13s. Thinking long term, I decided to order a set of factory bolts since I figured the 13mm head would be easier to loosen in the future vs the 12s. Plus the head on the factory bolt was meatier. Just made sense to go with factory.

Now back to stud discussion...

|

No worries it’s a place to discuss anything exhaust bolts or studs! 😁

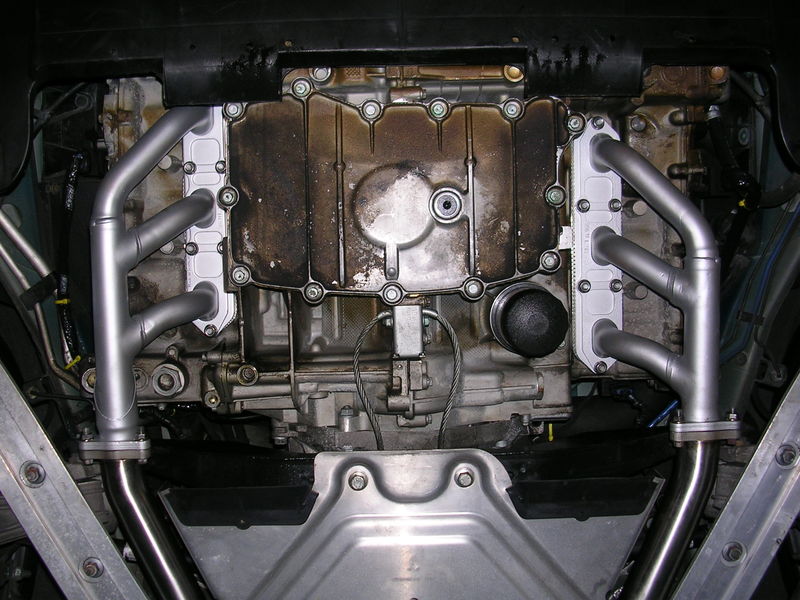

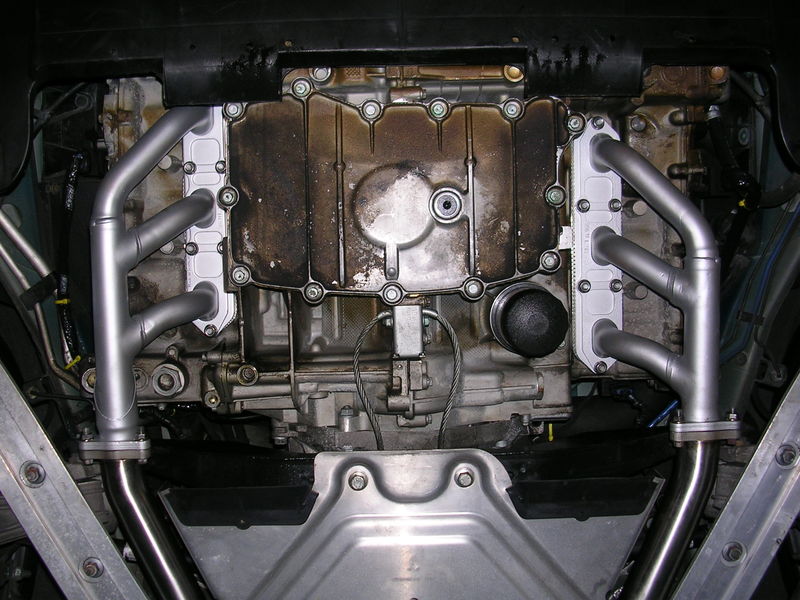

If I was to go bolts I would probably go factory. But I’m interested in studs for my new SS headers. I found a few SS studs and read put loctite red or blue on the cylinder thread and copper anti seize with copper nuts. I’m just afraid of messing up the cylinder head from corrosion (read about it somewhere) or them snapping in the cylinder and having a hard time drilling them out.

|

|

|

06-01-2021, 11:46 PM

06-01-2021, 11:46 PM

|

#16

|

|

Registered User

Join Date: Oct 2019

Location: California

Posts: 35

|

Quote:

Originally Posted by Dave80GTSi

I've used SS nuts on carbon steel studs over the past 4-1/2 decades of car exhaust wrenching, and have yet to encounter a single example of one seizing to the other.

As I said earlier ... Don't overthink this.

DM

|

Trying not to. Lol

|

|

|

06-02-2021, 09:09 AM

06-02-2021, 09:09 AM

|

#17

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by Johnny5

No worries it’s a place to discuss anything exhaust bolts or studs! ��

If I was to go bolts I would probably go factory. But I’m interested in studs for my new SS headers. I found a few SS studs and read put loctite red or blue on the cylinder thread and copper anti seize with copper nuts. I’m just afraid of messing up the cylinder head from corrosion (read about it somewhere) or them snapping in the cylinder and having a hard time drilling them out.

|

When installing one type of metal into a dissimilar metal. like mild steel into Aluminum.

Your going to get Galvanic corrosion. It is caused by an electrical process. The dissimilar metals actually create an electrical charge. Even if you use stainless steel.

So because the Engine block is Aluminum I use Anti-seize on things like spark-plugs, or exhausts studs- or bolts if I have to replace them.

If I have to replace an exhaust stud or bolt I use mild steel with Anti-seize. That way if I ever have to go back in and I break a stud off it is easy to drill out.

The practice of using mild steel exhaust studs with brass or copper nuts has been used in the Automotive industry for over 100 years.

They did it that way so that the nut would not seize to the stud from the affects of repeated heat and cold cycles.

The reason you see bolts now being used to hold the exhaust manifold on is because it is cheaper.

Profit is the driver. A bolt is one piece and one step. As opposed to two pieces and manufacturing processes. And two steps to install.

Use what suits your needs or what you feel is best for the situation.

Some may say I am over thinking it, I am just using what has worked for over 100 years for that specific application.

|

|

|

06-03-2021, 11:26 AM

06-03-2021, 11:26 AM

|

#18

|

|

Registered User

Join Date: Oct 2019

Location: California

Posts: 35

|

Quote:

Originally Posted by blue62

When installing one type of metal into a dissimilar metal. like mild steel into Aluminum.

Your going to get Galvanic corrosion. It is caused by an electrical process. The dissimilar metals actually create an electrical charge. Even if you use stainless steel.

So because the Engine block is Aluminum I use Anti-seize on things like spark-plugs, or exhausts studs- or bolts if I have to replace them.

If I have to replace an exhaust stud or bolt I use mild steel with Anti-seize. That way if I ever have to go back in and I break a stud off it is easy to drill out.

The practice of using mild steel exhaust studs with brass or copper nuts has been used in the Automotive industry for over 100 years.

They did it that way so that the nut would not seize to the stud from the affects of repeated heat and cold cycles.

The reason you see bolts now being used to hold the exhaust manifold on is because it is cheaper.

Profit is the driver. A bolt is one piece and one step. As opposed to two pieces and manufacturing processes. And two steps to install.

Use what suits your needs or what you feel is best for the situation.

Some may say I am over thinking it, I am just using what has worked for over 100 years for that specific application.

|

Well said! I believe you are dead on with it being a cost factor. On some factory vehicles they do use mild steel and copper nuts and I believe its as you stated its easier to drill out if it ever breaks.

What type of anti seize do you use? I was using regular but was told to start using nickel on spark plugs. Was going to use copper for the exhaust

|

|

|

06-03-2021, 12:59 PM

06-03-2021, 12:59 PM

|

#19

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by Johnny5

Well said! I believe you are dead on with it being a cost factor. On some factory vehicles they do use mild steel and copper nuts and I believe its as you stated its easier to drill out if it ever breaks.

What type of anti seize do you use? I was using regular but was told to start using nickel on spark plugs. Was going to use copper for the exhaust

|

So I use the gray ant seize on something like exhaust.

It is very fine aluminum in a petroleum base.

Messy crap

Copper anti seize (copper slip) is for applications like spark plugs where you want good electrical conductivity along with the anti seize properties.

Spark plugs ground via the threads in the block so Copper anti seize.

I have used the gray (aluminum) on plugs with no problems.

So really it could be used for just about any anti seize application.

I have not seen nickel anti seize.

But I wasn't looking for it either

|

|

|

06-03-2021, 01:13 PM

06-03-2021, 01:13 PM

|

#20

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Nickle based anti-seize has the highest temperature resistance, but can be used anywhere the other versions are in use. Amazon sells it.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 01:49 AM.

| |