11-26-2013, 07:30 AM

11-26-2013, 07:30 AM

|

#41

|

|

Registered User

Join Date: Apr 2012

Location: Riverside, CA

Posts: 1,666

|

Quote:

Originally Posted by The Radium King

different thread, but from a macro-environmental view, hydrocarbons make electricity, than you have the conversion losses, transmission losses, net present value of building/operating/replacing the new infrastructure required to fuel electric vehicles, disposal issues around batteries vs an iron lump of an engine, etc. a direct comparison of the efficiencies of internal combustion vs electric power isn't that fair. and don't get me started on dams ...

and back to ... kit car made out of boxster running gear!

|

Hurray...finally someone who understands where electricity comes from.

Yes folks, the US burns COAL amongst other things to make electricity and that is pretty much the most polluting of all the other electrical sources.

So just because there's no pollution in your neighborhood from your electric vehicle, don't think that its any less polluting than a combustion engined car.

Someday we may get there, but for now the US has hundreds of years worth of coal reserves to use up and a powerful lobby group to keep the Coal burning in the US.

I find that many of the so called environmentalist consumers have short sightedness when it comes to the big pictures and complete solutions and have

fallen prey to popular advertising putting blind faith in the marketers fairy tales.

__________________

"It broke because it wants to be Upgraded  "

2012 Porsche Performance Driving School - SanDiego region

2001 Boxster S, Top Speed muffler, (Fred's) Mini Morimotto Projectors, Tarret UDP,

Short Shifter, Touch Screen Dual Din Radio, 03 4 Bow glass Top (DD & Auto-X since May 17,2012)

|

|

|

12-01-2013, 11:51 AM

12-01-2013, 11:51 AM

|

#42

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by BYprodriver

I think I know what you are saying. Probably the most successful manufacturer is "Factoryfive racing" They make a 65-67 Cobra kit car designed to bolton 87-93 Mustang powertrain & suspension components. This is so popular they now make about 10 different kits mostly Ford based.

I worked for Shelby American 2+ years on the Shelby Series 1 project. This project had the full cooperation of GM & most of thier parts vendors, but after 4 years, still failed to meet my fit & finish expectations for a $150K sportcar.

|

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

12-01-2013, 12:11 PM

12-01-2013, 12:11 PM

|

#43

|

|

Registered User

Join Date: Oct 2008

Location: Gilbert, AZ

Posts: 266

|

Quote:

Originally Posted by BYprodriver

|

Agree, I've driven one on track and inspected it closely... the fit and finish is terrible. Even the Lotus Exige/Elise reminds me of nothing more than a refined kit car... although way more affordable and enjoyable than the Series 1.

|

|

|

12-01-2013, 12:45 PM

12-01-2013, 12:45 PM

|

#44

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

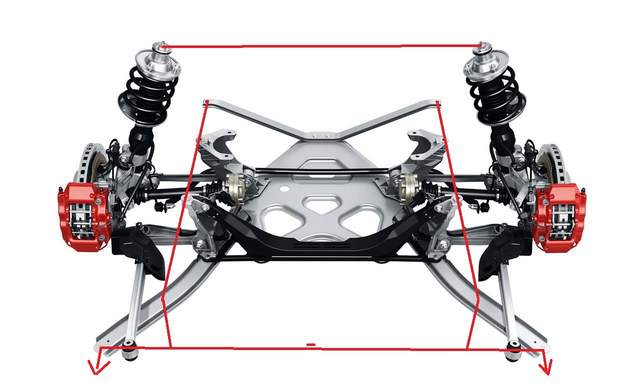

hey kcpaz, in your experience with boxsters, do you think there would be any economy/market in building a tube frame that utilised the boxster front and rear sub-frames (w/ steering, suspension, brakes, even engine/transmission)? from what I can see, if you use the complete assemblies, it wouldn't be that complicated - the front sub-frame is a pretty much stand-alone unit, and the rear as well. or just easier/cheaper to build from scratch?

|

|

|

12-01-2013, 01:54 PM

12-01-2013, 01:54 PM

|

#45

|

|

Registered User

Join Date: Oct 2008

Location: Gilbert, AZ

Posts: 266

|

Quote:

Originally Posted by The Radium King

hey kcpaz, in your experience with boxsters, do you think there would be any economy/market in building a tube frame that utilised the boxster front and rear sub-frames (w/ steering, suspension, brakes, even engine/transmission)? from what I can see, if you use the complete assemblies, it wouldn't be that complicated - the front sub-frame is a pretty much stand-alone unit, and the rear as well. or just easier/cheaper to build from scratch?

|

I think from a business standpoint, kit cars in general are a really tough market. Businesses like Factory Five are a rare success story. How do you predict what consumer will want (design wise)? And then how much money will someone need to invest in molds, chassis fixtures, custom glass, rubber seals, door hinges etc... It's the same way with marketing engine conversions, but on a smaller scale. Everyone wants something different. In engine conversions for example, some people want LSx, Subaru, Audi V8, VW 4 cyliner, and within each of those choices, there are a lot of different ways to configure each option. Imaging how you would decide which kit car to build.

|

|

|

12-02-2013, 08:30 AM

12-02-2013, 08:30 AM

|

#46

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by The Radium King

hey kcpaz, in your experience with boxsters, do you think there would be any economy/market in building a tube frame that utilized the boxster front and rear sub-frames (w/ steering, suspension, brakes, even engine/transmission)? from what I can see, if you use the complete assemblies, it wouldn't be that complicated - the front sub-frame is a pretty much stand-alone unit, and the rear as well. or just easier/cheaper to build from scratch?

|

For a track toy maybe, I think the key is the required level of fit & finish. The Shelby Series 1 used mostly Corvette C4 suspension components, bolted to a custom aluminum tube frame/tub. C4 steering knuckles were used front & rear by swaping sides in the rear like a Boxster. C4 knuckles are forged, C5 knuckles are nearly identical but not forged. Shelby's contract with Oldsmobile included free GM parts for the 1st 5 prototype cars. Shelby was allowed to buy production intent parts directly from the vendors that manufactured them. I was amazed to see the largest C4 brake rotors (13.5" Z-51??) cost $37.50.

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

12-02-2013, 10:25 AM

12-02-2013, 10:25 AM

|

#48

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

very simplified (struts would have to get tied into the main assembly, more cross-bracing would be required, etc.) but the concept is there.

Last edited by The Radium King; 12-02-2013 at 10:27 AM.

|

|

|

12-02-2013, 10:41 AM

12-02-2013, 10:41 AM

|

#49

|

|

Registered User

Join Date: Oct 2008

Location: Gilbert, AZ

Posts: 266

|

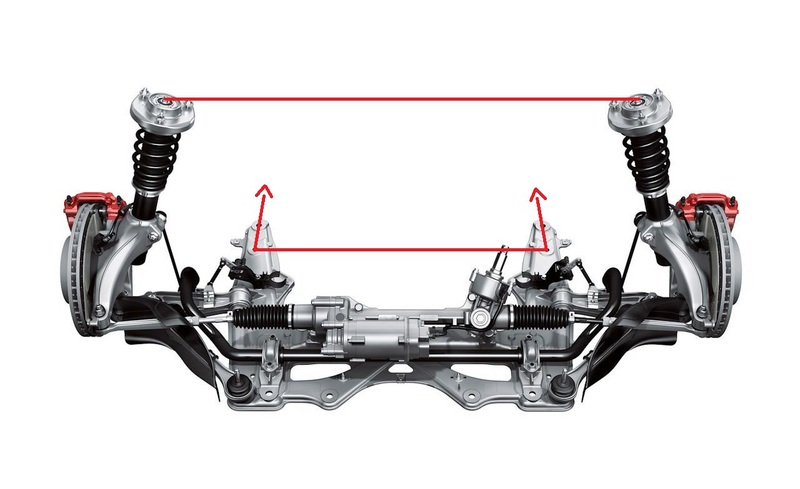

Also, if I were going to build a kit car, I would not use a strut type suspension. Too many compromises and the height of the strut limits body designs. I would do an a-arm suspension using the Boxster uprights

|

|

|

12-02-2013, 10:48 AM

12-02-2013, 10:48 AM

|

#50

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Yeah pretty easy, just opposite of how to make a billet wheel where you just cut away everything that doesn't look like a wheel.

Actually, once the Series 1 engineering team of 3 had the C-4 suspension mock up in place it took almost a year to finalize the aluminum square box tubing frame. Although this was a DOT & EPA approved street car using GM passenger car subassembly's mostly from the F-body cars. Chief engineer was really good & best boss I ever had. Once we finished the 5 prototype test cars & production car issues he went to work for Multi-Matic in Canada.

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

12-02-2013, 10:50 AM

12-02-2013, 10:50 AM

|

#51

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

aha. I wondered about that. I looked at my favorite body designs and wondered how they kept the hoods so low and still accommodated the struts.

|

|

|

12-02-2013, 10:55 AM

12-02-2013, 10:55 AM

|

#52

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by The Radium King

aha. I wondered about that. I looked at my favorite body designs and wondered how they kept the hoods so low and still accommodated the struts.

|

Rocker arms & pushrods. (designed by Multi-Matic)

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

12-02-2013, 11:09 AM

12-02-2013, 11:09 AM

|

#53

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

I guess that was what I was really wondering; once you step away from plug-and-playing the oem components and going with a rocker or a-arm suspension then it would probably cheaper and easier to start from scratch than to try and jimmy-rig the oem stuff.

|

|

|

12-02-2013, 11:34 AM

12-02-2013, 11:34 AM

|

#54

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by The Radium King

I guess that was what I was really wondering; once you step away from plug-and-playing the oem components and going with a rocker or a-arm suspension then it would probably cheaper and easier to start from scratch than to try and jimmy-rig the oem stuff.

|

Irregardless of what you do you will be in a generic, other, experimental, class. Dead Boxsters will soon be plentifull due to the high cost of a good engine. I choose to build a good 3.6 engine, if the car is totaled or stolen I transfer the engine to the next chassis, reap the profit & carryon. It's probably the luckiest break Thstone ever had!

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

12-02-2013, 03:46 PM

12-02-2013, 03:46 PM

|

#55

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

here's the body (vortex automotive gt):

has a bit of a 360 thing going on from the side, some old 246 from the front, but still manages to be a bit english at the same time. just needs german mechanicals. I like it.

Last edited by The Radium King; 12-02-2013 at 03:49 PM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 12:38 PM.

| |