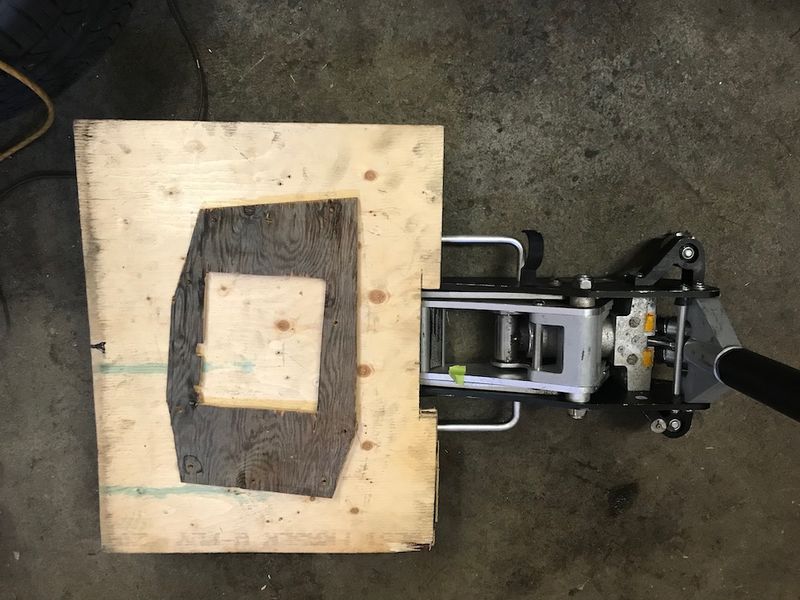

Hopefully I have found the best way to do an engine swap with my equipment. I have constructed a new low-rise dolly that is designed to allow the floor jack to slide under it.

First I bolt a piece of 1/4"" plywood with the center cut out of it to the oil pan, so the weight is on the edges of the pan not the somewhat fragile center. The engine is placed on the dolly and pushed under the car. Working from the front I roll the jack under the car than under the dolly and start lifting. There is a separate transmission jack under the transmission. It is then a question of raising the two jacks an inch or two at time while checking the clearances. I did a swap this way, working alone, and it went pretty well. I was worried that the engine might tip sideways on the jack, but it was fairly stable but I had my engine hoist in place with a strap around the clutch area as a backup.

Bottom of the dolly