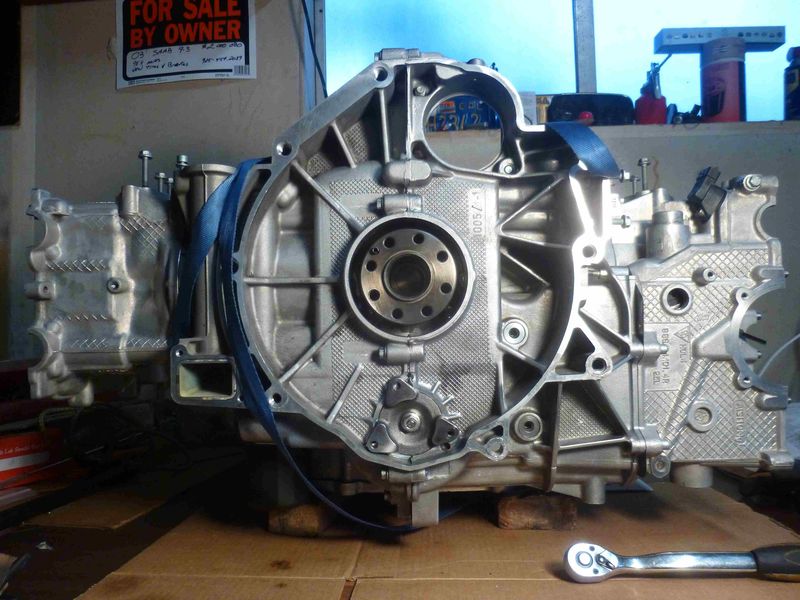

I took the engine off from the engine stand and placed it on the workbench to get access to the rear side. It`s getting very heavy now and I almost managed to drop it when one of the straps snapped. I`ll double the straps or switch to some heavy duty chain from now on.

IMS flange is refitted with new O-rings and a bit of sealant.

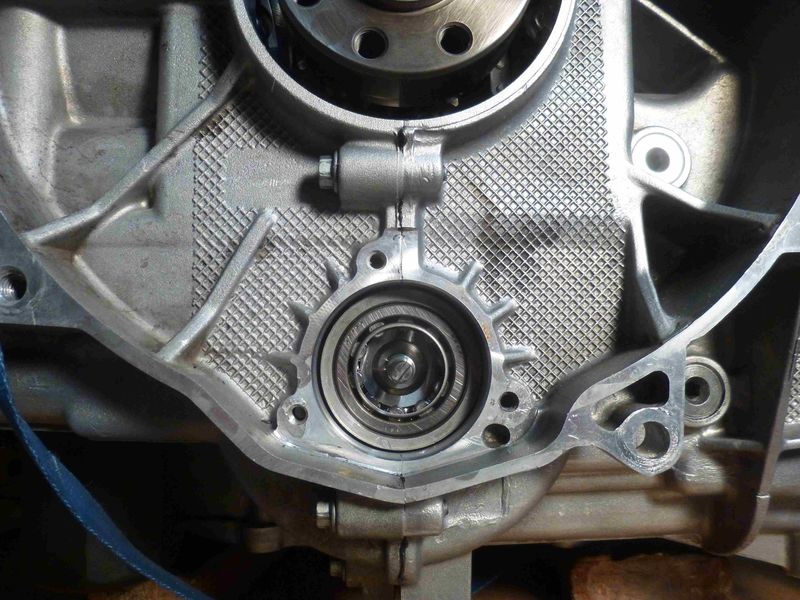

Time to fit the tensioner. There are three tensioners in this engine, they are all alike, but not the same. They are identified with the number of rings, 1, 0, or 2, hard to mix them up. Pretty thoughtful.

New O-ring and aluminum gasket.

Now to the rear main seal. I needed a tool here so I went to a local hardware store to find something I can use.

And I found this. (Without the holes of course.) It`s an end cap for some PVC drain tube, exactly the same size as the RMS. This is my lucky day..

After cutting it to size, it worked perfectly using the flywheel bolts and the old seal as a guide.

Hopefully it won`t leak.