I received all the parts for the crankshaft assembly, so I put it all together last night. A pair of new bearings, oil spray jets, one thrust washer and new bolts.

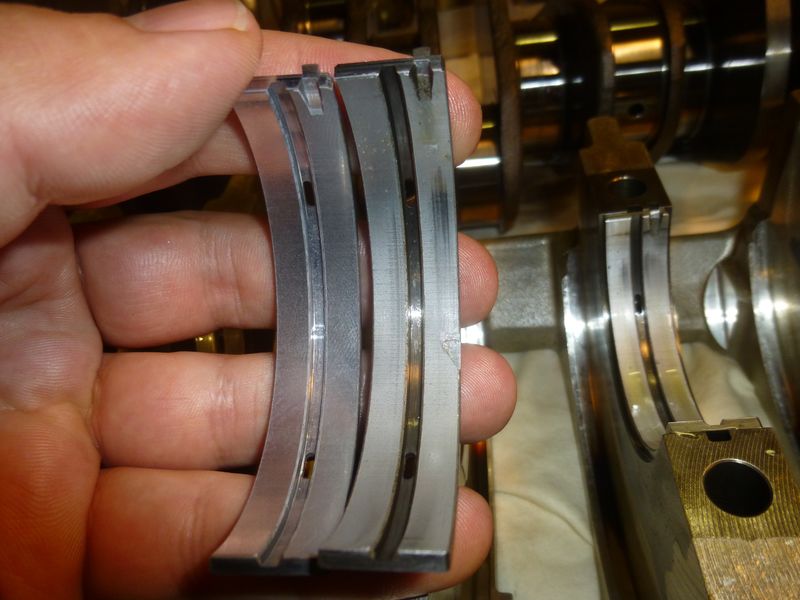

Old vs new bearing shell:

Old vs new thrust washer: the new one has three of those oil pockets, otherwise it`s identical. This was the only version available.

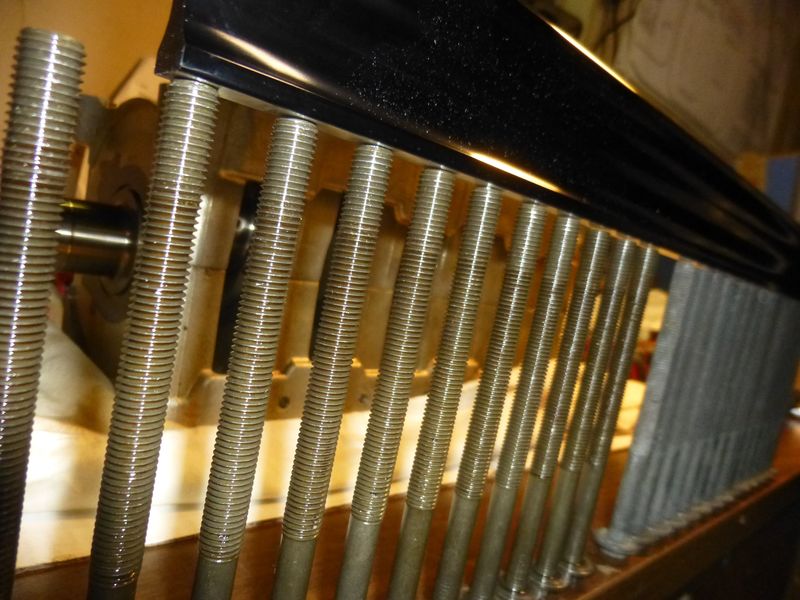

The 14 bolts for the bearing carrier are the TTY (torque to yield) type, so it should be replaced at every reassembly. Out of curiosity, I quickly looked at how much the old bolts were stretched by lining them up on my work bench and placing my straight edge on top. No difference. I might as well just reuse them, it`s more reassuring to use new bolts though.

I flushed the oil galleries of the bearing housing and the crankshaft oil channels thoroughly by injecting gas using a large syringe.

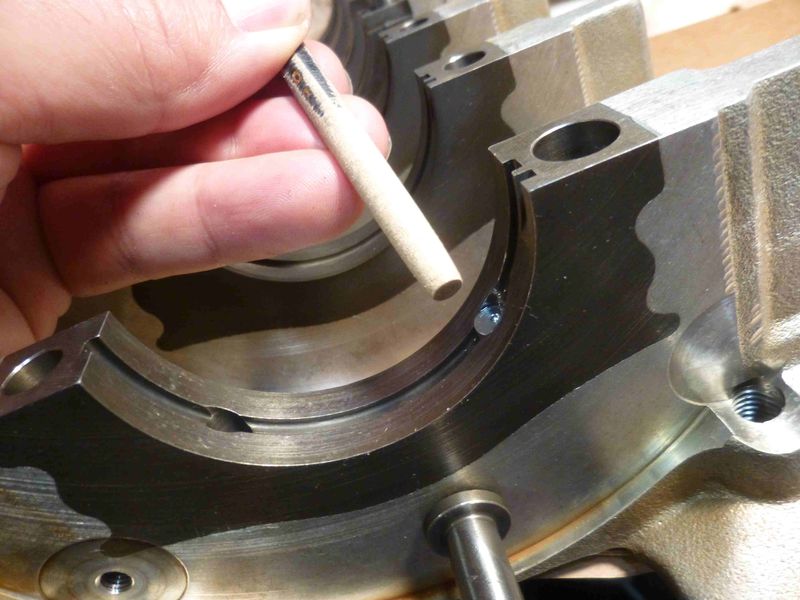

New oil spray jets/splash valves.

I don`t what`s the proper way to guide the splash valves into their bore without damaging them, I used a pencil that I sanded off to match the size of the jets. To avoid filling the little hole with graphite ( don`t ask how I know this) I wrapped it in a piece of rubber glove material.

Looking good.