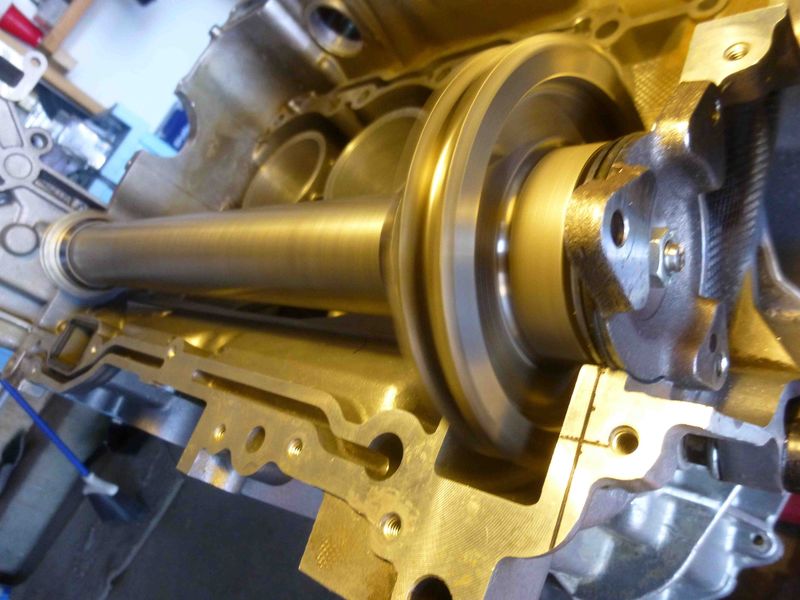

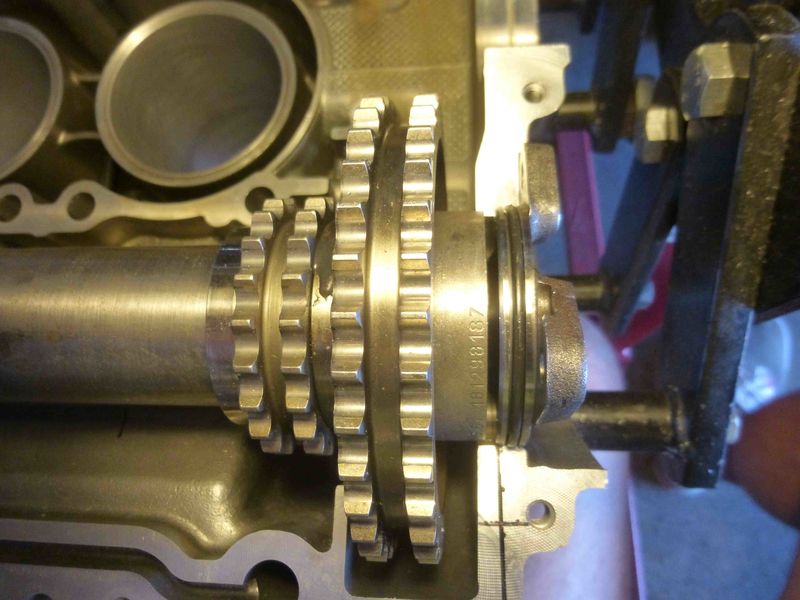

The whole unit is submerged in oil normally that I think is sufficient for lubrication. However, oil has to find its way around the IMS that spins in the engine case.

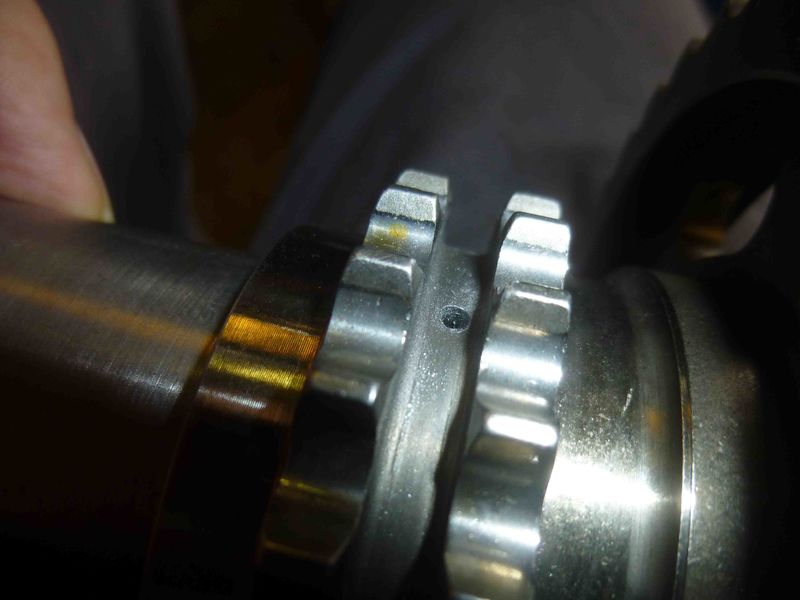

Here`s a closer view. At high RPM and at certain viscosities much of the oil may be scattered off from the shaft due to centrifugal force. This may increase the chance that the bearing is not amply lubricated at all times.

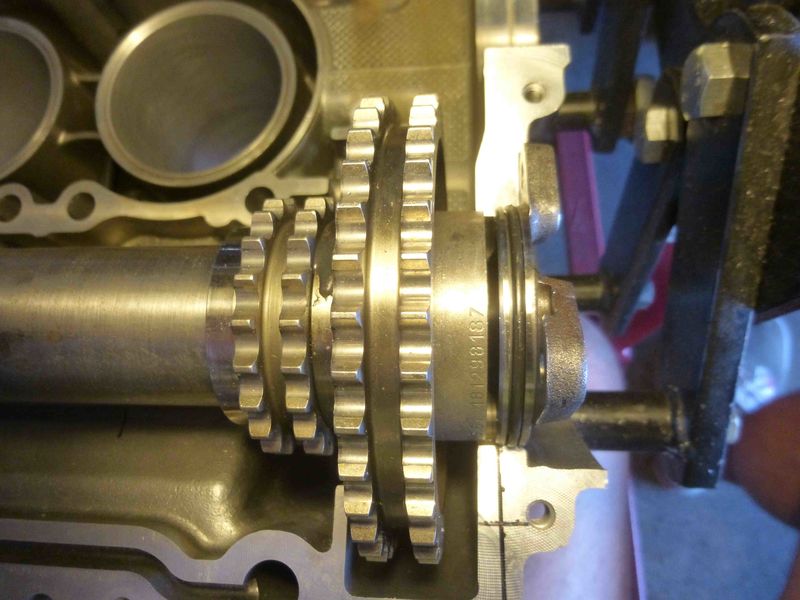

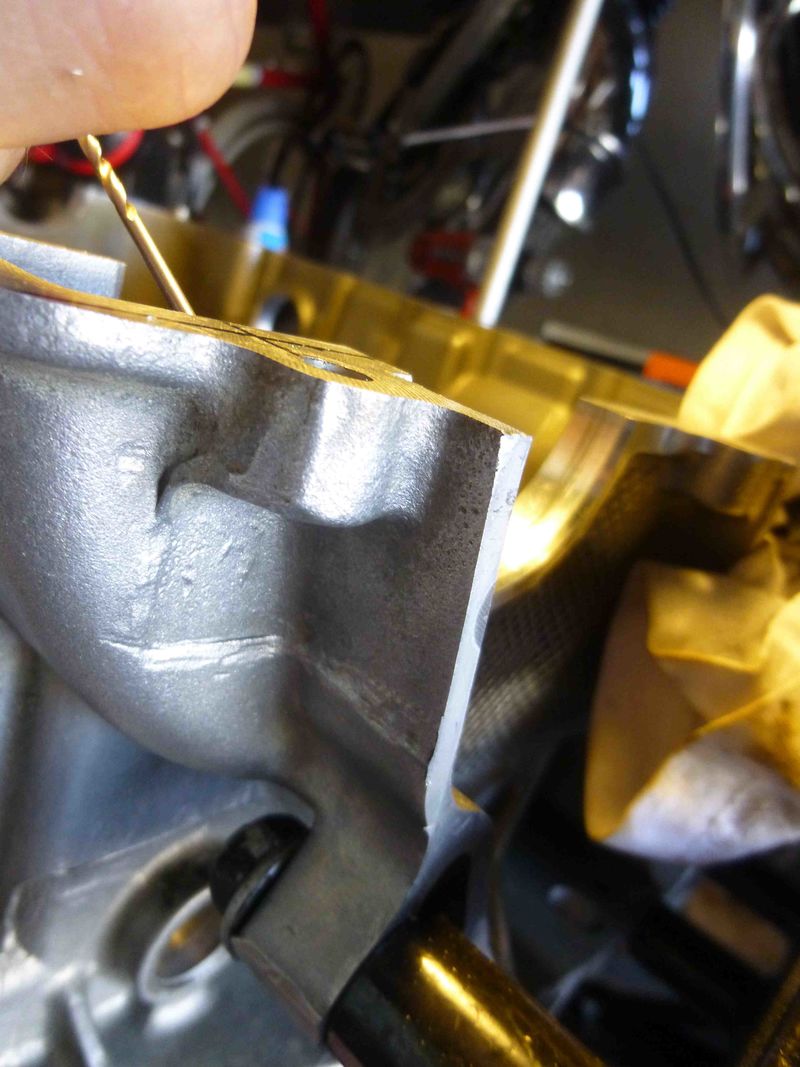

Probably it`s overkill, but to overcome this possibility, I thought a bypass oil channel in the engine case could set the same oil level behind the IMS in all circumstances. So, after a few second hesitation I decided to drill an oil gallery in the engine case. There`s not much room here, so I fabricated a mini drill to do the job:

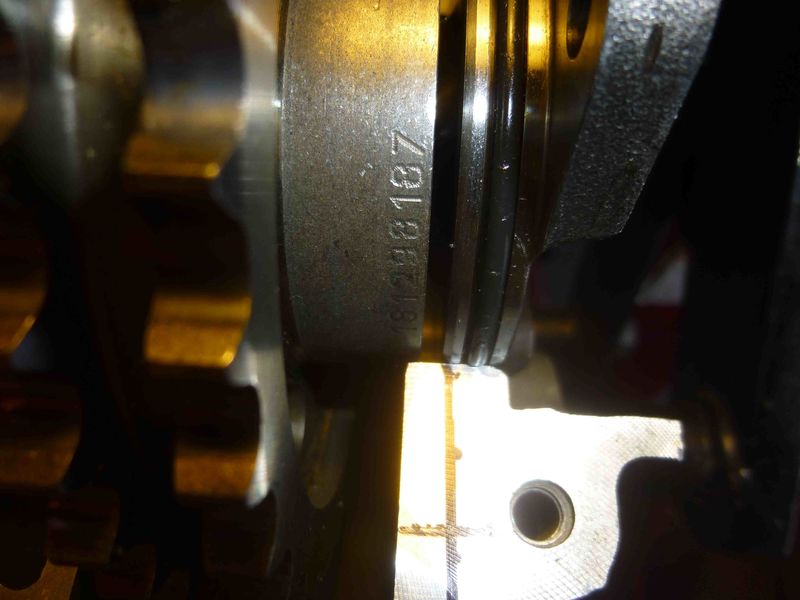

Engine case wall is pretty thick here, so there`s plenty of room for a little oil gallery.

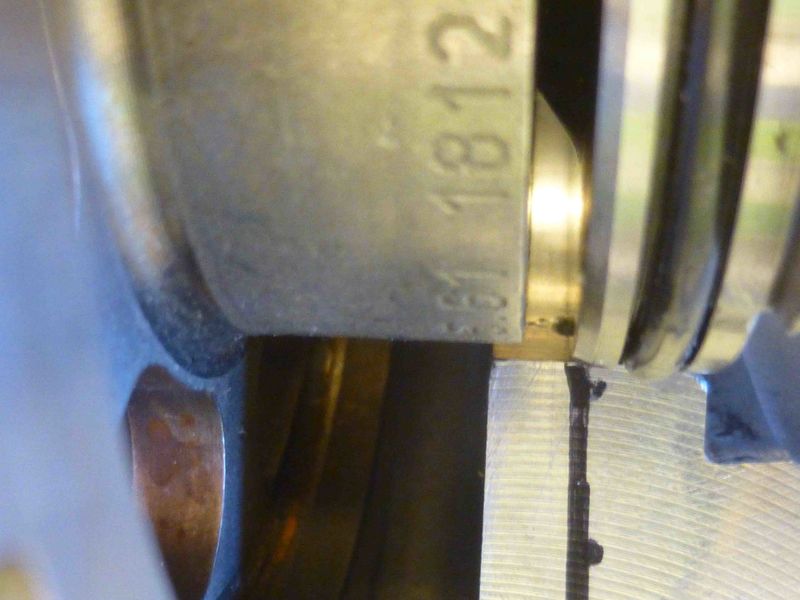

In situ position. Horizontal lines indicate the oil level at min and max sign at the dipstick.

Oil should easily reach the stationary center parts of the IMSB unit via this hole.

The oil gallery actively contributes to the better lubrication of the IMSB as well: the spinning sprocket generates a high oil pressure in its cavity that forces oil into the gallery and thus the back of the IMS.

Oil within the IMS gets depleted via this small hole drilled on the sprocket.