^ All very fancy pics, does it work?!

What a weekend. The dogs kept on barking randomly at some night critters the whole of Saturday night so most of us didn’t get sleep. Well, I did LOL but the others hardly slept (oops!). We stayed in 5* tents, of course (camping!).

Oh well. We came back at lunch time so I am already upstairs in my office carrying on the design validations (CFD) on our assembly while the wife and my puppies are catching up some good sleep. I am only doing flow atm… pointless to include coupled thermal at this stage, all we need to know for now is whether the heatsink I’ve designed a few hour ago is getting an ‘effective’ flow of fresh air.

^ Omitted in previous screen grabs is the front of the assembly. Nothing to show really… other than the frame that caps off (seal) the whole enclosure. That frame is modeled to accommodate both the IPS display & capacitive touch screen (sandwiched together).

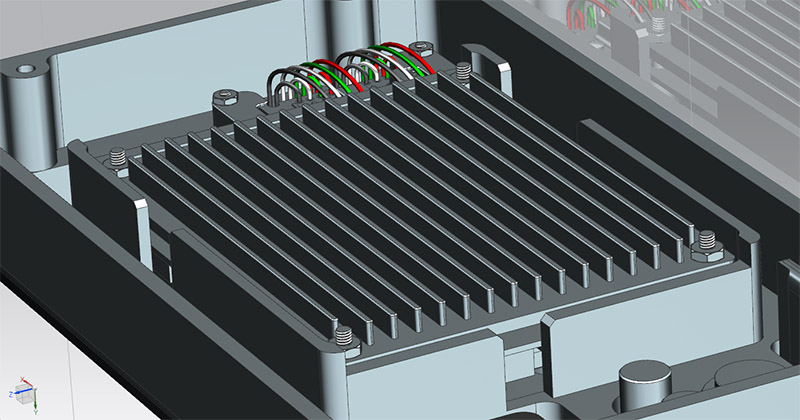

^ Using a straight ‘fin’ system for our heatsink here. The whole idea was to get fresh air flowing between the fins with very little resistance/drag. Pins are also very effective, however in a design like ours, they would simply create excessive turbulence. So for us, fins are the most effective way.

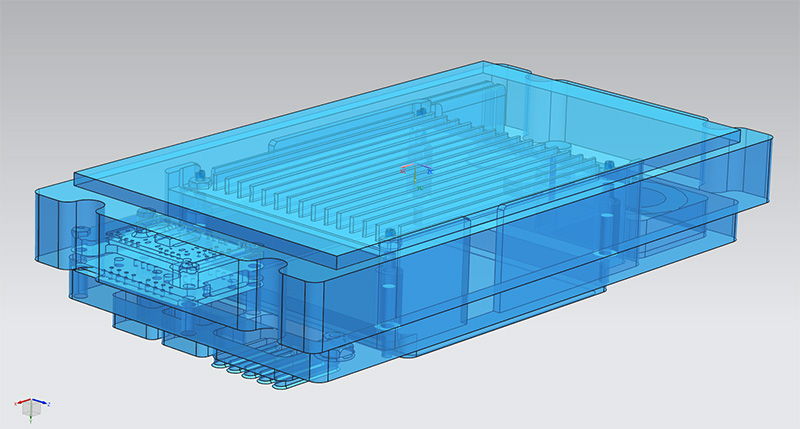

^ Above is our fluid domain. It is the core fluid from our sealed assembly. Essential step to all CFD analisys. Inserting this pic because those fluid domain are quite difficult to extract. This is accurate to 0.2mm.

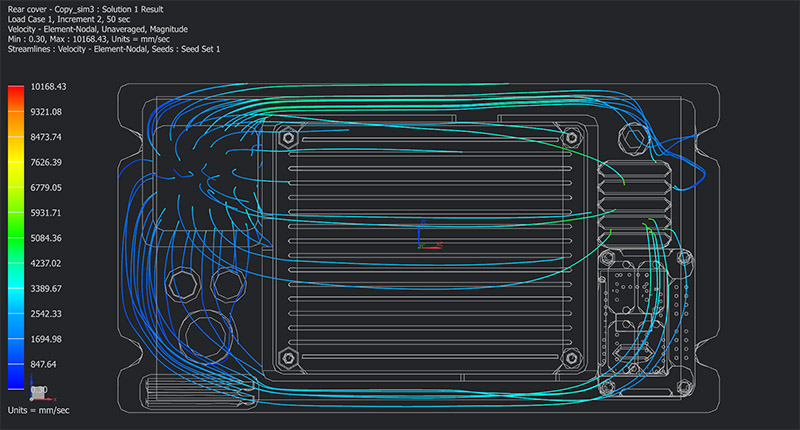

^ The-End-of-the-world here. Preliminary CFD on our design/assembly fails huge. As you can see from the grab above, we are not getting a ‘flow’ on the heatsink. We are surely getting so air (air is air) but not effective at all. My intention of having a inlet and outlet positioned the way they are now was a good one but results are not satisfactory.

^ Oh hang on, we are actually getting 'some' air (air is air!), but nothing like what I was aiming for. That is so NOT going to cool down my CPU and GPU, pretty useless in fact. Don't even bother doing thermal validation with this LOLL

So at that stage, we might as well just buy those $200 Asian (Android?) 2DIN kits. Those aren’t professionally thermally managed and often heat up to 90~100degree Celsius on a good summer day (I’ve heard/read a few weeks ago only).

The other option is to stop crying and fix our design by blocking where the air likes to go and channel ALL of it onto-our-heatsink! Sounds easy but let's see lollll I’ll get this done in a few hours and re-run the validations. This does NOT go into my machines for prod if no proven thermal management comes out before lollll

I'll update later this eve