I'm no pro and am trying to figure this out myself. Hopefully Qmulus will correct me if I'm wrong about any of this, but here's my advice.

With the car stripped, the harness does come out relatively easily. Start at the ends disconnecting everything and work your way to the major bundles. In a stripped car, all the terminals and connectors will fit through the firewalls. Gradual push and pull, nothing should need to be stressed.

I am going to be modifying a harness as I do an engine swap. Here are a couple videos that I think are good info.

I like the process in this one, but I think that his crimping (tool and connector) are the weak points.

This video looks like good advice on crimping and soldering. I like his tools and proceedure:

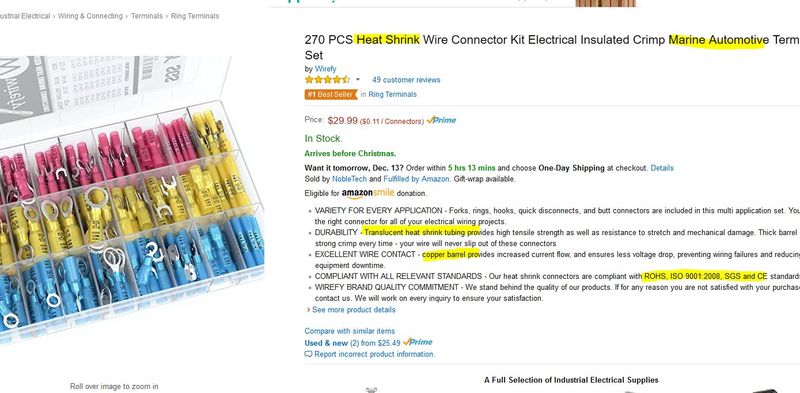

For a crimp connector, my guess is that these are a good choice: