Quote:

Originally Posted by itsnotanova

Great thread! Thanks for the compliments earlier in the thread. Can we see more pics of your $5 bearing puller?

|

Woody, you get the thanks! You have supplied many needed parts at a great price and fast shipping. Without your support, this would be a much more expensive project and take much longer.

So, now to my cheep Yankee puller. This is not an indictment of anyone else or their products. This is more an indictment of me being cheep and somewhat clever.

For most of us this is a one time use tool. I may need to do another IMS bearing because I'm a serial Porsche owner and project addicted. I have pulled a lot of bearings in the past and didn't see the need to invest a few hundies in a single use tool that to me isn't all that unique. I searched for folks that had made their own puller and cam holders, and found nothing on the interwebs, so I was on my own.

I have lots of junk tucked away in my 2 car garage/shop. I'm always puttering on cars and have a few projects going all the time. I typically over buy small things because I don't want to run out to pick little stuff up when doing a job, and this is where this exhaust pipe part came in. Allie was messing with the 944 exhaust system a few years ago and while out I grabbed a few adaptors that were $2.79 each. She didn't need some so it got thrown into a box of "muffler" stuff for use later or maybe never, but I don't throw good stuff away. Here's Allie after she got done welding up here "test" pipe to replace the cat.

Enough bragging, back to the puller.

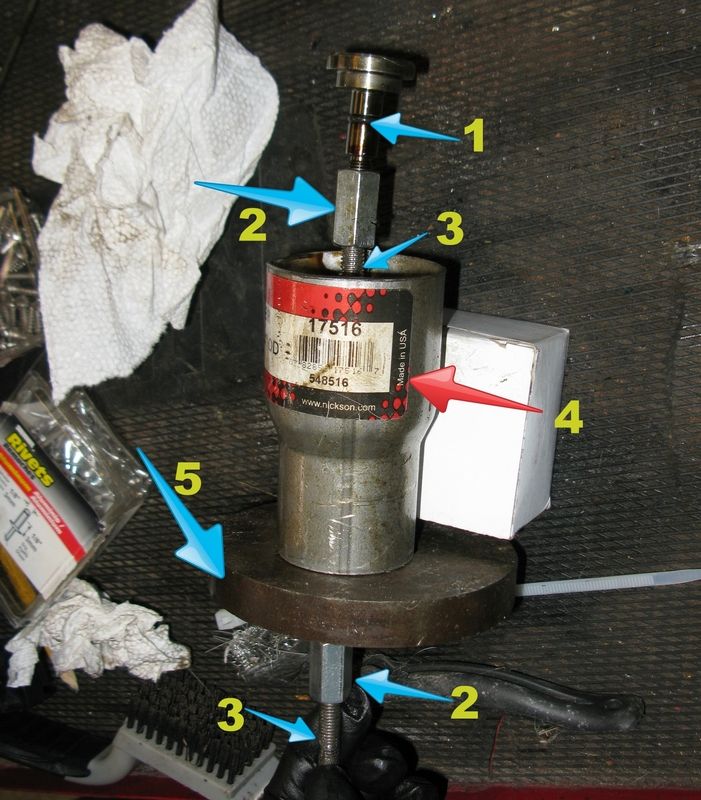

The pipe is strong enough for the job to pull the double row with the wire keeper that it has. The OEM bearing stud is 8mm ( #1 in the picture below ) with what we would call a fine thread or a pitch of 1.0, so the standard coupling nut( #2 below ) must be threaded to 8mm 1.0 from the standard 0f 8mm 1.25 pitch. I didn't re-drill it, I just grabbed a 8x1.0 tap and cut the new threads on 1 side or 1/2 deep on the coupling nut #2. The threaded Rod ( #3 in the pic ) is 8mm 1.25 thread pitch so only 1/2 of 1 of the nuts needs to be rethreaded. The pipe is just an off the shelf exhaust pipe that is sold in every auto parts store. The only dimension that matter is the ID (inside diameter) of the end that goes on the end of the IMS pocket. The OD (outside diameter) of the bearing is approx 1-7/8" OD so you need a bit if clearance for the bearing to come into. The pipe I used is a Nickson 548516

Autozone info:

Nickson 2.00" I.D. x 1.75" O.D. Reducer

Part No. 548516 $3.99

I don't pay full price at the local parts store, I paid $2.99

You MUST use a coupling nut as the part that you turn and introduce the load. The standard nut will end up stripping the threaded rod. The normal threaded rod isn't made from the strongest material like a normal bolt. So I used a second coupling nut to wrench on and lube it up with some slippery grease. #5 is just a scrap piece of steel with a hole in it for the threaded rod to some thru and cover the end. I also used some washers becasuse the hole was like 1" so I needed to shrink this down to 8mm. You can grab a piece of plate 1/4" from your local dirt floor weld shop for free, take it home and drill an 8mm hole in it and you are good to go!

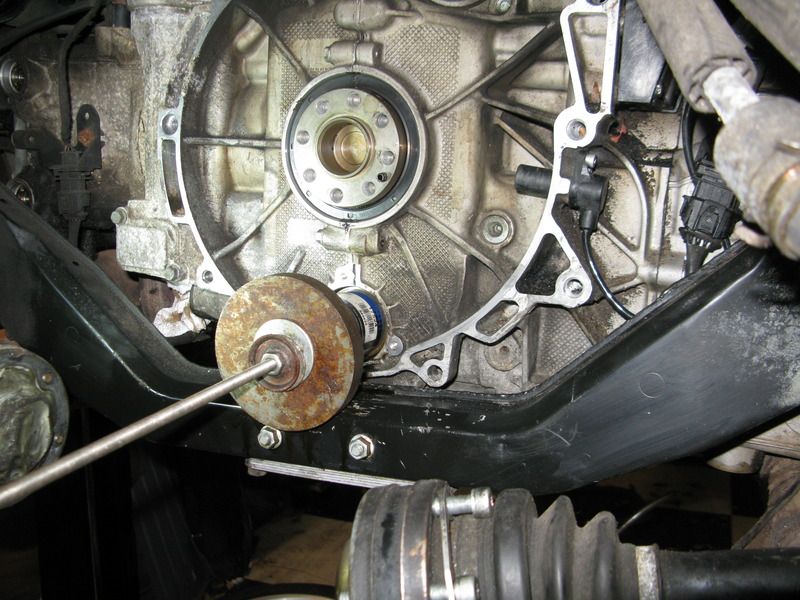

The puller during first fit up. The pipe shown has the wrong ID so I changed it to the 2" ID part. the "normal" height nut will not work.

I hope this helps.