Quote:

Originally Posted by Ben006

An engine is basically a pump, but the the air behave the same if you move it by droping the pressure on one side, or raising it on the other.

There is no such thing as vacuum, it's just a difference of pressure and that is what move the air, a fluid is never "sucked" it is always pushed from an area of high pressure to an area of low pressure.

|

Explain why on these charts the wedge makes no difference and in Pedro's video it does and he calls it pulling air and says there is an influence on the air

Quote:

Originally Posted by blue2000s

I'm using Fluent in these simulations.

A Y will be more efficient than a T for airflow in a steady state, that's correct.

Keep in mind that with three cylinders to a plenum, there is a pretty much constant flow of air into the plenum when the engine is kept at a constant speed. There is always a cylinder pulling air. The pulses that influence secondary pressure waves are important, but they are secondary in nature so the influence on flow is on a much lower order than the primary vacuum pulled by the cylinders themselves.

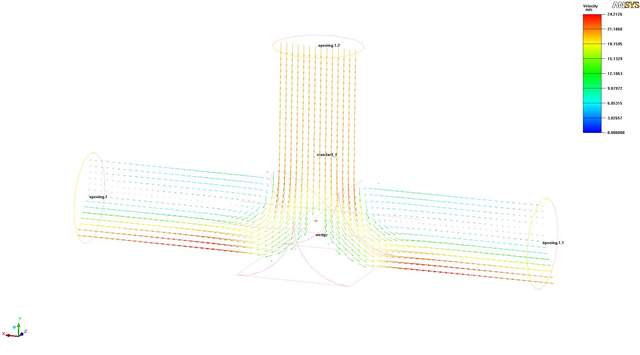

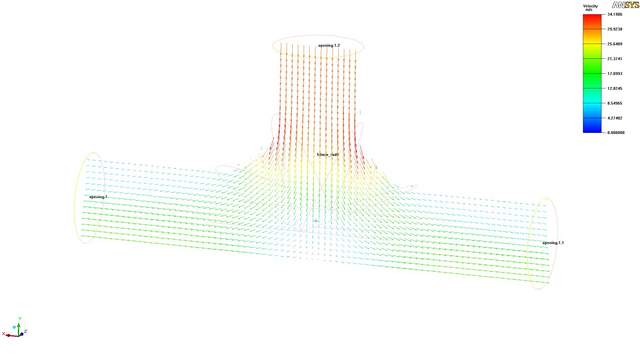

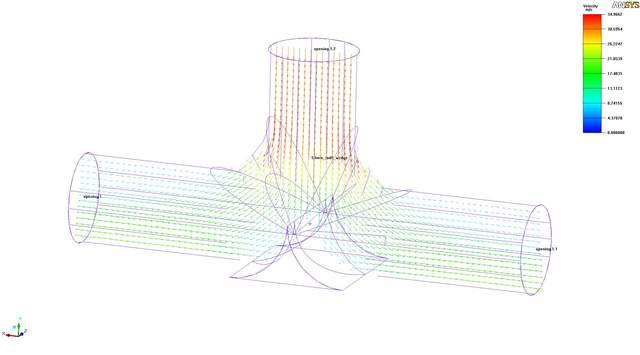

Here are three more simulations varying on the one I posted earlier. The first one just adds a sloped wedge to the original T. The second adds a large radius to the T junction and the last one combines the radius with the wedge.

The volume flow rate results show that the T and T with wedge have almost identical flow rates. The radius-ed T with and without the wedge are both almost the same flow rates but are about 30% greater than the standard T. |

We have this.

"A third factor in manifold vacuum is engine compression. If an engine has low compression in all cylinders, it creates a steady, but low, manifold vacuum. If an engine has low compression in one cylinder, manifold vacuum will be low only

during that cylinders intake stroke. This will be observed as a gauge that fluctuates or quickly changes reading. Low compression in a cylinder can be caused by leaking valves or rings, leaking head gaskets, or other ways that keep the cylinder from sealing during the compression stroke."

Compression and Vacuum

Quote:

Originally Posted by jsceash

The instant the air starts to move Newton's laws apply. It doesn't mater if it suck through a pipe or push through a pipe the same principles apply. The same equations are used to calculate flow loss, flow velocity.

This must be another theory that doesn't apply and can't be taught in Kansas school.  |

Do you know how to have a conversation without insulting someone? If you can't, you can go you know what yourself. Also read my location again smart guy, I don't live in Kansas.