Quote:

Originally Posted by Jake Raby

Too often we are seeing shops have their opinions swayed from a profit perspective. They may not have any experience with something that they are recommending, yet they support it because its the part that helps their bottom line the most.

This is usually because it's cheap and may even be falsely advertised as "patent pending" or by stating the parts are German, when they are actually fitted with a Romanian bearing.

Too often the shop doesn't care; if something fails they just blame the part, throw up their hands and say its not their problem.

As the retrofit that we invented becomes more mainstream, thats what the industry has dealt with. Lots more motivates recommendations than just a component design, or benefit, and as a consumer you need to base things on m ore than one recommendation.

|

Jake, I see you referenced me AGAIN in your post. This is why I decided to give you a quick answer, but you might not like it. It will definitely lower your and LN's ratings. Recently, I praised you publicly for your good work, IMS solution, and even recommended your solution to my customer! I was hoping you will stop self-praising on the forums, but I see there will be no end to it. This is why I have decided to present everyone with the straight facts so everyone else will see how you love the self-serving stuff on the forums. You really are unlucky today because we do have yet another LN bearing which is already starting to fail, slowly but surely. You accused me on rennlist of fabricating the failures. First LN failure we mentioned on this forum- bearing was completely destroyed. I knew we would get back to this subject, but never thought it would be so quick. Second LN failure we had in our shop was when customer from Ca sent his core in exchange for our rebuilt motor. He started a tread on rennlist, we also started one on this forum. So you can fully understand the situation, I buy 4-6 Porsches from auction per month. I try to find cars with low mileage and minimal damage. Once I get them in, we remove the engines, transmissions to resell here in US. Then, we ship these cars to our shop in Poland, where these cars get another European engine installed. That way we do not have to send our European engines to US. I have purchased 7 cars like that within the last month. Before we remove these motors we test them, record a video, and upgrade IMS, rms, water pump, etc...

Here's your bad luck: one of those engines (3.6l) had LN bearing installed, 52k miles on the motor. We always remove the factory bearings from used engines and install our roller ims bearing upgrade. BTW Jake, we use Japanese bearing, not Romanian. Let me know if you need one, I can send you a new set, which is easier to install too (you said you had problems with our original set). We made it simpler after your complain that it took to long to install.

Anyway, the bearing removed from that 3.6l motor with 52k miles was LN single row. I doubt it was there from the start, it's a 2003 so I assume it has been "upgraded" maybe 20k miles ago. Today, I have removed this bearing (using your tool) and took it apart because it was a little bit loose adn was making a slight noise. It appeared ok at first, but upon further inspection it turned out to be much more loose than it should be and it got me curious to see what the races look like. I have pictures

For comparison, I have both LN bearings in pics, one I removed today, and the other from that customer's engine (failure#2).

Regarding your IMS removal tool, you claim you were the first one to invent it. Wrong. I have removed many bearings, mostly motorcycle (I race since I was very young) which have similar design, with different tools available in Europe and worldwide. They have been invented a long time before you did. It might not have been the same tool, but essentially provided the same function. Take a look at the bearing which is just starting to wear out, it's nicely visible under a magnifying glass.

I will not get into another debate with you. There is no way to win with you. My every argument gets a counter argument from you. You will wear me out trying to convince me that you're right, it's a waste of my time and energy. I know what I know, some other engineers and experienced mechanics also know what I'm talking about. I will not try to convince you because it makes no sense. You have to stand by your design and your products.

Regarding that: we do stand by our products, if anything should ever happen, we will help our customers, unlike LN which always blames the installer, engine or misalignment. Our bearings are working ok, no failures so far, how is that possible? You have just recently discovered a "misalignment" issue, and you now sugest that our customer's bearing failed because of that. You created another new issue which has really nothing to do with it. You have to realize there are many other misalighments in this car, it's not an F1 or Moto GP motor, which costs 1.5 million dollars. These engines have no misalignments, every single part has to be perfect because it can cost them a spot on a podium. These teams spend millions on racing and they don't fool around. I have seen this with my own eyes, I race motorcycles and I know what I'm talking about. Factory accounts for the possible misalignment when they release their engines, but again these are not million dollar motors from F1 or Moto GP. Therefore it's supposed to last long enough to run. Factory engineers have calculated the possible misalignments in different components. BTW, there is a flexible chain connecting ims shaft with crank shaft and that allows for the alignment to be off.It's not a transmission case where shafts have to fit ideally and there is no tolerance of play. Why the factory allows bigger misalignment in engines but not as much in transmissions? They know it will work.

If I were you I wouldn't waste time thinking about misalignment but instead try to find the correct material which will withstand a small bearing with big load. Until then, use your solution and leave us and others alone and let them use roller bearings. I don't have to sell my bearings, I make enough money on repairing engines and selling used motors. I don't care if I sell another roller bearing, or if people will buy it from Vertex or someone else. If I cared about it I would be everywhere talking about it. If someone wants to buy it great, if not, I don't care or tell them what to do.

How come we see your bearings failing all the time? Either you're extremely unlucky or we are extremely lucky! I will not be surprised if one day I buy an insurance auction car with one of your motors. I will definitely take it apart to see how the nickies are doing.

I have attached pics of both bearings. The one I have removed today has minimal wear, but it's already visible. If you look closely you will find tiny spots of wear on outer race. There are tiny spots on inner race too, very minimal and hard to see. The material on both races is starting to peel, and as bearing gets more worn out it gets loose.

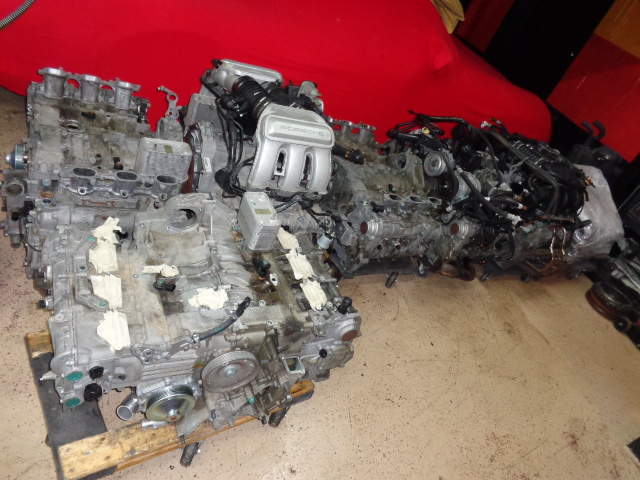

Picture of our used engines, we removed LN bearing from one of these:

Picture of our customer's outer race:

Picture of our Japanese roller bearing:

Our kit:

Comes with a handle to hold the bolt during installation:

I'm currently working on an IMS pattent which will be your IMS solution competition. It's not for sale yet, once I get a prototype and pattent pending everyone will hear about it. I thought of it after our last public fight. Jake and other forum members were my inspiration. I heard your voice and I listened. People are looking for inexpensive, DIY IMS that will be easy to install and work forever. All I can tell you is when it comes out people will have another great IMS option to install in their cars, and will save money on engine repairs from then on. There will be no pre-qualification needed, and this will be the last part to break inside of any motor. Even if it breaks, it will have no effect on that engine. Customer will be able to drive the car home or to the shop to get it replaced. This is what Porsche owners need and asked for, they will save money on engine repair once it comes out! I plan on including my IMS pattent in all of our engines. It will also be available for sale and easy DIY installation. Believe it or not, I'm having the Germans make my prototype! They have been running a machine shop for the last 45 years, and they work wonders. Solid German work!