Few of you guys requested some more info about the optional angel eyes kit RE how they sit the bezel, material used ect. Someone else reminded me about the theme of this thread, which is to document every steps taken in the making of those high performance projectors, w/ pictures of course! Fair enough I'll say

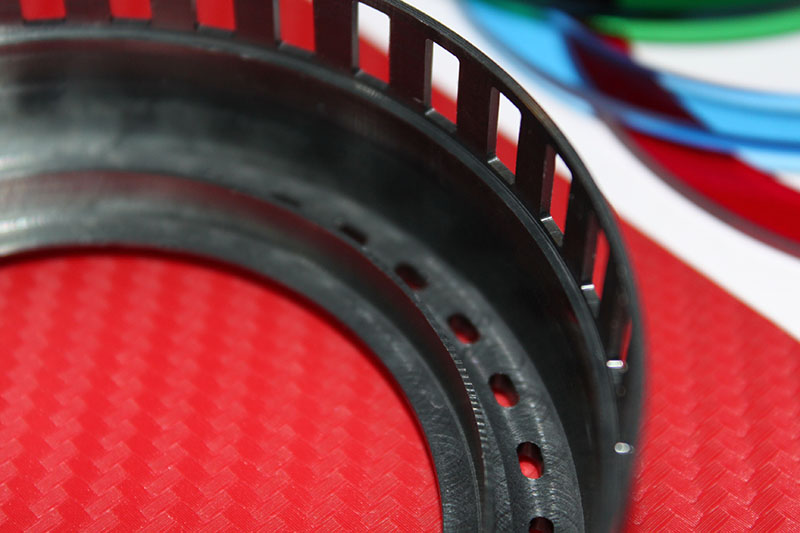

^ All starts with a completed bezel. In this case, the Great Gunmetal Gray style!

^ Once anodized and laser'ed with customer's custom script on the face, they are ready to be implanted an angel eye (lol)

^ Somebody is missing his early high school years obviously. However most material you see there have been fine selected and thoroughly tested.

- 2mm thickness acrylic color filters

- 0.1mm thickness photography LED light diffuser film (very expansive, $4 per sheet, doesn't change color due to heat or time, ultra thin and 100% opaque)

- A set of COB LED angel eyes in white color

- Top quality Thermally Conductive Epoxy Resin/filler (A+B) and application syringe. (I get this for free knowing someone close to me working in this industry haha)

^ In this case I'll be using a clear acrylic filter for white angel eyes. But I have them is pretty much all other colors! They all create a very soft but vivid light output.

^ I've tested many different types of angel eyes COB LED rings during the whole of December. Those are the best you will find in the world at the moment. The 90 LED are covered by a resin (no vibrations) and the circuit is built-in to the PCB.

One LED goes off and you still have 89 working! This + a 2mm thick filter and you are certain that the angel eyes' light output won't be broken or affected by a burnt led.

They are rated @ 20,000hrs and known as The Best in the industry.

^ They also come with the proper heat resistant wiring, both the angel eye and wiring passed tests @ ~300 ºF for 120min continuously (amazingly).

Decent connection are in already place however everything gets re-enforced later with thermally conductive resin.

^ This is the cavity that is machined inside the bezel to accommodate the angel eye, the filter & the diffuser.

^ Assembling in order: 1) clear acrylic first 2) opaque diffuser second 3) angel eye third 4) Thermal conductive epoxy resin

^ Final assembly covered with a few drops of the thermally conductive epoxy resin. The thermo epoxy resin is rated @ ~500 ºF

* ZERO light escape from behind there, no lens light pollution

* Vibrations proof, no movements, no condensations, no hot spots along with effective heat dissipation materials. MAX temp emitted from the angel eye is 90~96 ºF (or 36 ºC). Very low!

* Safe, stable and durable along with a stunning natural looking & diffused light output.

The most advanced and simplest angel eye design you'll ever see.

There you have it!