I need to share this with the forum, someday when you get to 255,000 miles on your motor you might have to deal with this.

This P0410 alarm has been haunting me off and on for the last year; it became constant these past few weeks so it was time to fix it. I found it interesting that I did not get the P1411 at this time like I did when I had a broken vacuum line. I thought maybe the O2 sensor in front of the catalytic converter bank 1 was bad but I checked that and swapped sensors but no change.

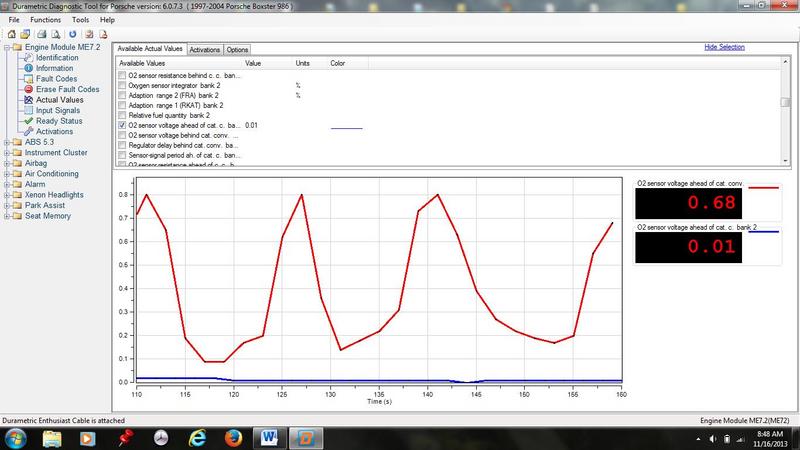

Here is what Durametric showed during cold start-up with the SAI Pump running P0410 alarm (O2 Sensor Voltage Ahead of Cat):

Bank 1 voltage should have been very low like Bank 2.

I inspected the SAI system but did not find anything bad, all components checked-out (I love removing the alternator).

Then I decided to inspect the air ports in the heads going into the manifold so I dropped the manifold/catalytic converters and found this:

OK, cut me some slack, the motor has 255,000 miles on it and bank 1 is original catalytic converter and has never been removed.

As most of you know carbon is a pain to clean but there are a couple of products that seem to do a good job at breaking it down. Sea Foam is one product that I have used in the past, so here is what I did… I purchased a pump/syphon and some 3/8” tubing. I shoved the 3/8” tubing into the SAI port on bank 1 and put the other end into an empty container. Then I shoved the pump into the SAI port on bank 2 and pumped/circulated Sea Foam from one side to the other. Let the Sea Foam set for a few minutes and did it again.

Then I cleaned all the orifices with a piece of copper wire and the rail with a nylon brush soaked in Sea Foam.

Then I used the “Turbo Snake” to clean the main orifices. On bank 1 I had to chip away some of the carbon with a screwdriver before I could get the snake into the main orifice. The snake did a good job reaching in and scraping inside the head. Then I flushed with more Sea Foam and used my air compressor (thanks JFP for that advice) to blow the air injection tube and heads clean.

Now the heads are much cleaner and openings back to normal.

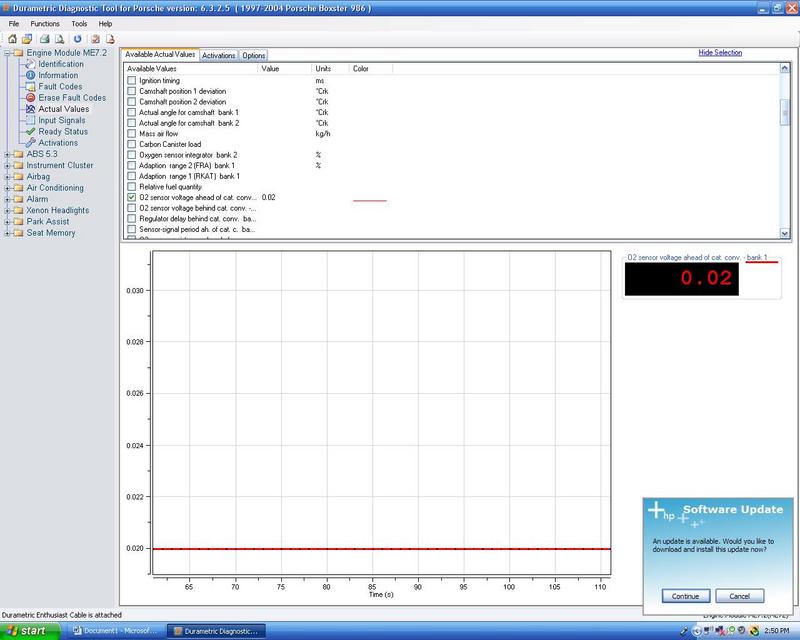

I put things back together and started the motor with the SAI pump running and this is what the Durametric shows now:

0.02 – 0.00 volts is much better than the .1 to .8 volts (sine wave) I was getting before. Now it looks like the exhaust manifold/catalytic converter is supplemented with the proper O2 levels at startup. I suspect this fixed my P0410 alarm.