The projector's mounting design is final. The prototype machining is completed and the assembly have been tested. Again, all carried out with emphasis on simplicity (Plug&Play), lightweight, and rigidity.

A 40mm spacer between the projector and the headlight reflector was required. Without the spacer the whole assembly was hidden (tucked) inside the reflector. Now the shroud's features can be viewed from most angles; top, front and sides. Looks absolutely fantastic (pics of this coming soon).

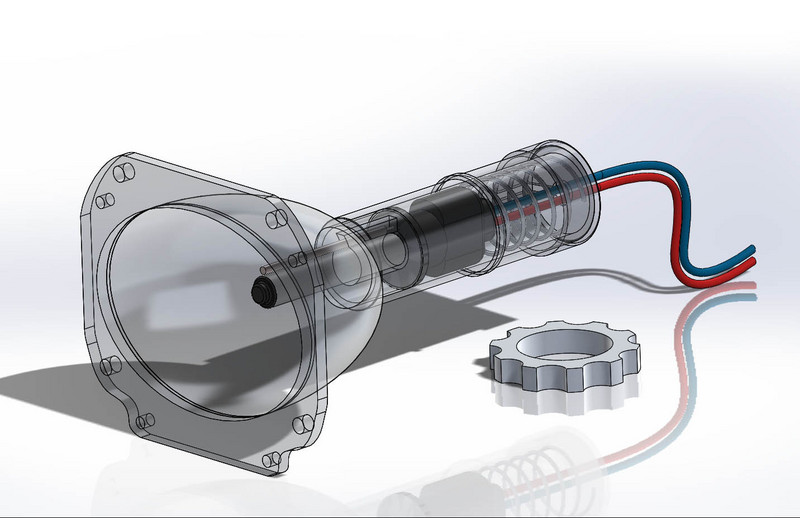

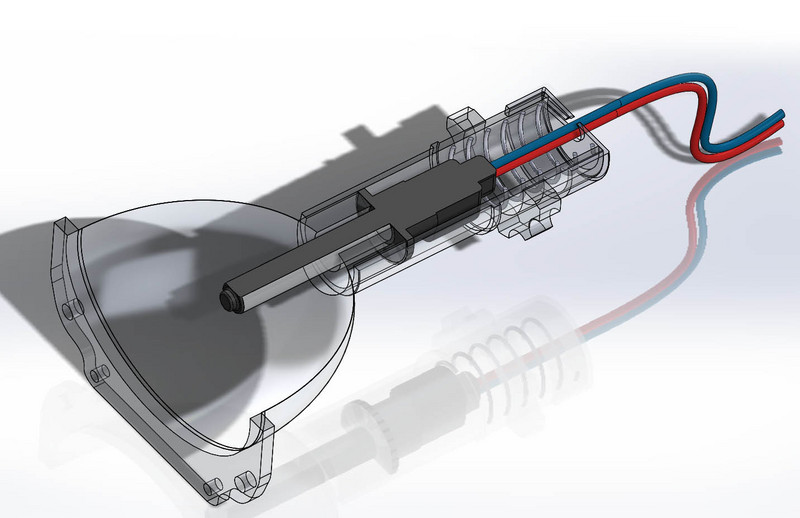

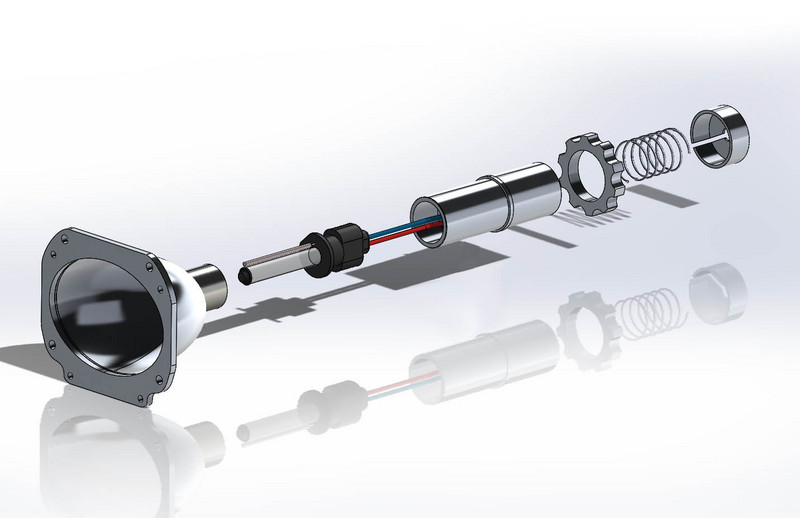

For now, here goes the model and other visuals of the projector mounting assembly.

^ This is how the kit comes really (and will ship). How easy!

^ This is how the kit comes really (and will ship). How easy!

^ The kit after anodizing. Yes I anodize everything but for good reasons:

1. the parts last a decade (min) without showing any sign of fading

2. the anodize layer is extremely hard, making the aluminum parts and their finishes indestructible

3. non-conductive surface. when anodized, the part lose its conductivity feature. A must when engineering parts near electrical systems.

Now off the headlight preparations & painting. I'll update as soon as I can

/