Finally done selecting the paint after completing a non-stop 67hrs cooking session at 225degree on two different unit. Without a peel or a single bubble. I'm pretty convinced the unit will be able to endure a few years of medium to hot weather.

*Design update*

I've designed a custom lens mounting system to achieve a simpler assembly. Therefore no more fitting PVC cylinder and gluing shroud ideas! What I got now is a solid and lightweight aluminum complete unit. Installation should be as easy as replacing a light bulb.

Other than that not much more. I've shorten the shroud by 10mm making it look a bit more like the Carrera GT lens. It's now 30mm in length. Looks far better imo

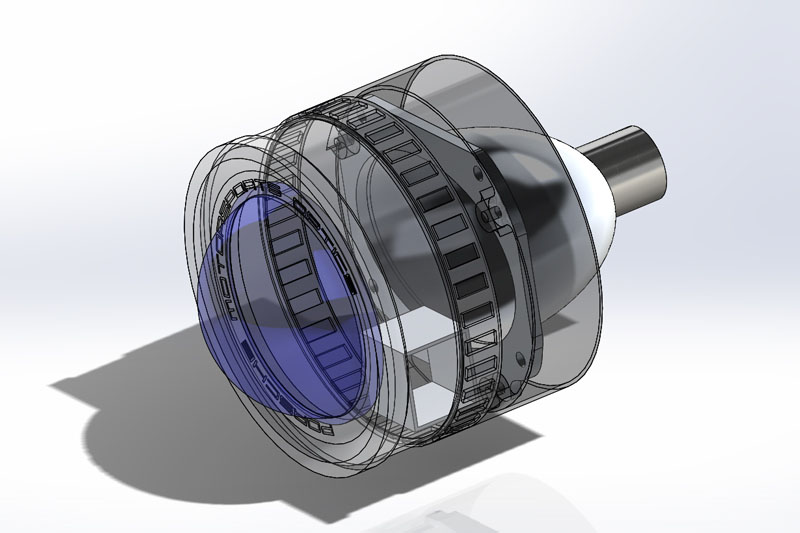

See through view. I haven't bothered to model the cutoff plate and the solenoid. They do not interfere with the design so pointless to waste time there.

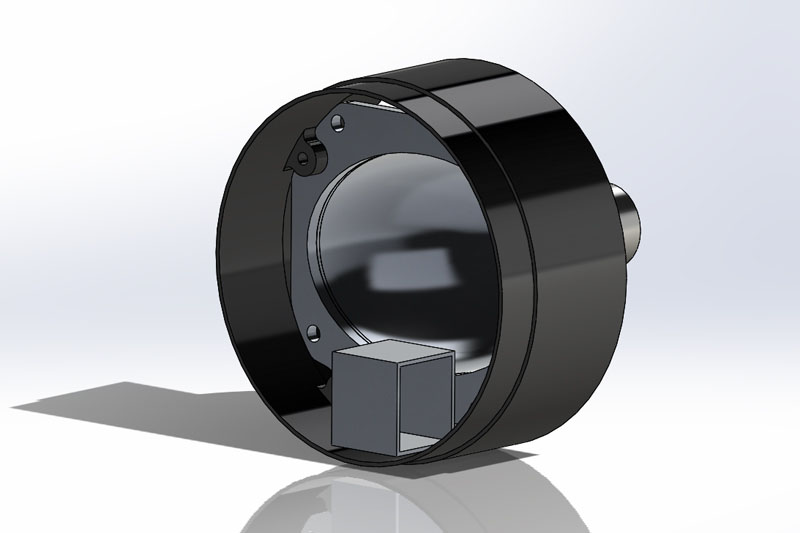

Sliced view of the assembly. The weird box inside is are only proportions and represents the compartment for the solenoid ie. the coil that activate the cutoff plate (high/low beams flip flap thingny).

How the unit will be assembled. The four tabs of the skirt will be secured with SS304 M4 screws, shroud and lens mounted with 1,300 degree high temp industrial epoxy (very expansive stuff, and unforgiving).

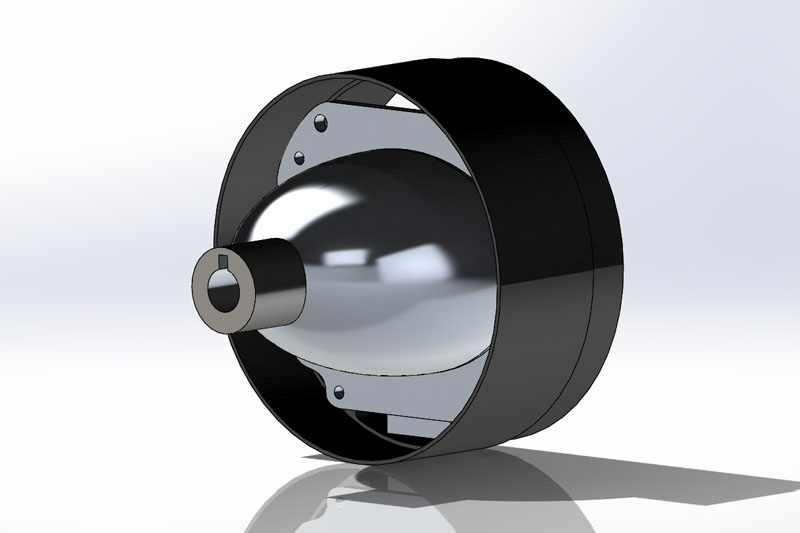

The back view. I've left two ventilation ducts. Unfortunately I am being told by the manufacturer of the projector that the unit can't be closed completely. This is to ensure the longevity of the HID bulb.

Rendering of the assembly. This is the whole unit really. Clean and Plug-&-Play!

Will update as it goes. Moving on to shopping for materials tomorrow, CAM work thursday and production on Friday eve and (very possibly) the weekend as well. We'll see how things pans out here.