Quote:

Originally Posted by pjq

If the home DIY'r is able to reassemble the engine to factory tolerences, get the weights correct on the crankshaft connections and then manually turn the crank and it feels smooth and rotates easily how do we know if we truley got it exact, because I'm getting the idea these Engines are suppose to be exact.

At a engine rebuild shop do they have machines to check themselves as they go?

What about when you finally bring the engine up to 6 -7000rpm and it must be smooth, do rebuild shops have machines for this or is it the experience of the builder?

Since balance is so important how can we replace our own clutch assembly and not mess up the fine balance, surely there is slight weight variations in the new parts? From what I read and see you take off the old flywheel, disk, plate and bolt on the new, there is no rebalancing happening at this stage?

Any thoughts?

|

It's more about preparation of the parts before you begin assembly. Insure every part you are putting into the engine is up to the task you are assigning it. (Daily driver for another 150K miles + autocrossing, or 30 minute lap sessions on track, or 24 hours of Daytona race.) The engine is only as strong as the weakest link. (part)

Find the best engine balancer you can send the reciprocating assembly to: Front crank pulley,bolt & washer, crankshaft, rods & bolts, pistons & pins & circlips, new flywheel & pressure plate, consider sending a 2nd flywheel & pressure plate since most balancing shops can't balance the flywheel & pressure plate without a crankshaft to mount on.

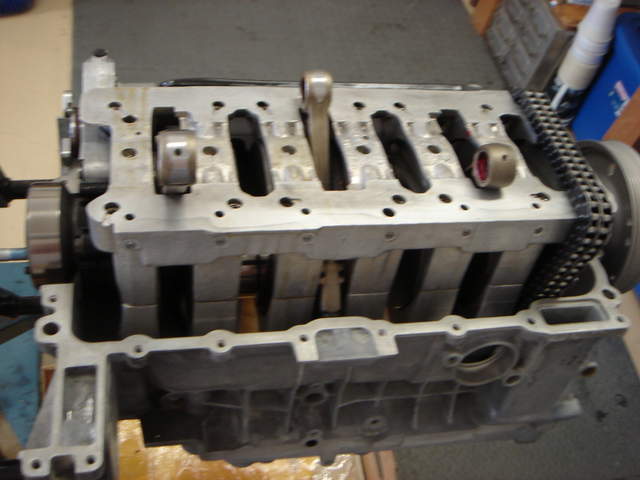

Usually very little material is added or removed as seen on the rods in the picture below.