|

A few additional thoughts...

A few things I forgot to mention in my original post, in no particular order:

- Just my opinion, but completing the wiring in the engine compartment will be MUCH easier if the car is on a lift. Seeing where to locate it, zip tying it in place, etc. - these things are possible when you're lying on a creeper with the car 16" or so off the ground, but if there's any way you can get it on a lift for this part of the project, life will be much more enjoyable. I did everything else with the car on jack stands, but when we drilled the hole in the firewall and routed the wire, it was on a lift...

- Use the Loctite sparingly... you need to lay down a bead that's 1 to 1.5mm wide. That's about .05" A little goes a long way. There's NO reason to go overboard. BTW, the the 50mm tube contains way more than you'll need for this job. When everything was buttoned back up, I cleaned out the applicator spout, put a small piece of plastic wrap over the opening of the tube, and then screwed the applicator back on. There was plenty left over for future use.

- A nit: the written instructions tell you to remove the plastic baffle from the sump plate before cleaning the plate. They never indicate that you're to reinstall the baffle. You need to do this. (Fortunately, the video shows the baffle on the plate when the sump plate is being reinstalled.)

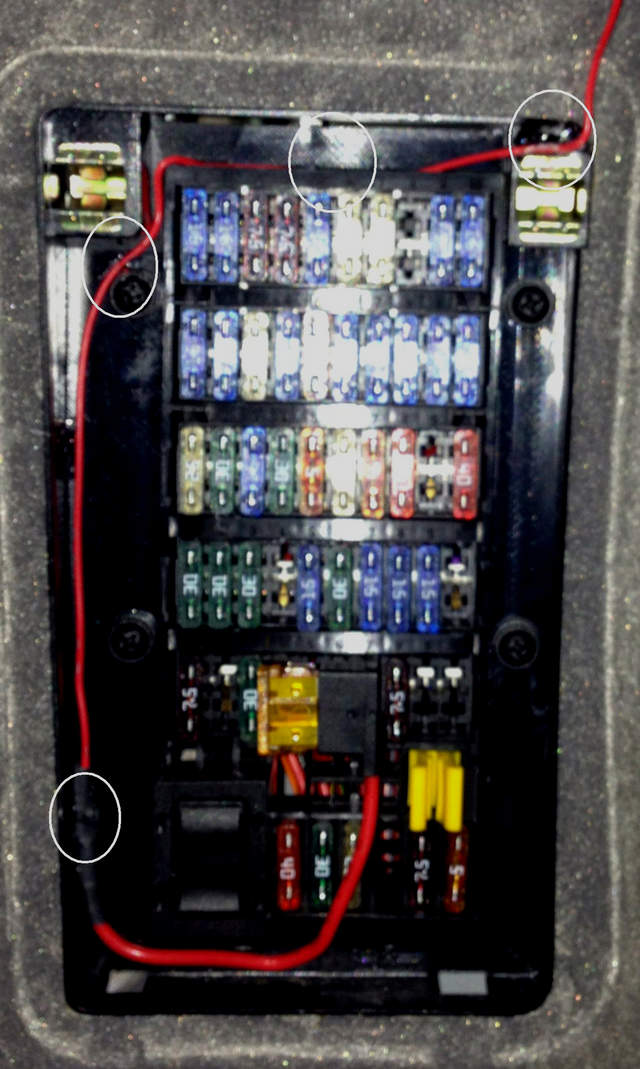

- A photo of the wire in the fuse box; circles indicate where I used a little hot melt glue to secure it (sorry, ugly pic):

- Feeding the power lead to the fuse box: there's a spot to the upper left of the LH switch panel port that's perfect for this. You don't have to feed the wire forward, deeper into the dash, and then down. Just look to the left side of the opening when you remove the LH switch panel (on LH drive cars).

- Finally, when I torqued the MCD, the difference between hand tight and torqued to 37 ft. lbs. was nowhere near a "quarter turn." My advice? Get a socket modified or buy one from LN, and use a torque wrench.

April 2013 EDIT: NOTE: per Jake Raby, the MCD should be torqued to 19 ft. lb., NOT 37!! Torquing to 37 will damage the MCD.

Good luck!

__________________

2000 Boxster S, 6 speed, Sport Package, Litronics, LED tail lights, LNE IMS-B, OBC, Skybreaker wind deflector, Arctic Silver/Graphite Grey

Last edited by kjc2050; 04-19-2013 at 04:27 AM.

|