Having completed my IMS Guardian installation, I thought I'd share a few observations and tips in the event that someone else tackles this project.

First, an overview: I completely changed the order of the various steps in this process.

Flat 6 says to do:

- Disconnect battery negative terminal

- Drain oil

- Remove sump plate and clean

- Install MCD, hand tighten

- Reinstall sump plate

- Torque MCD

- Fill with oil

- Change filter

- Install wiring

- Connect to MCD

Reading the instructions and watching the install video, it seemed to me that the most difficult part of the job was going to be the wiring installation. You have to feed wires from one side of the center stack to the other, and in my car, the HVAC and radio are in the way. Also, the instructions for feeding the main wire through the firewall looked as though that process would be difficult.

So I took a different approach:

- Installed wires in passenger compartment, but didn't connect; ran wire to firewall, hiding behind console and carpeting

- Removed firewall carpeting

- Tried several times to figure out exactly how to feed the wire through to the engine compartment, gave up

- Drilled one inch hole in firewall, installed rubber grommet and fed wire/MCD connector through to engine compartment

- Removed plastic shield beneath engine

- Ran wire to appropriate spot near bottom of engine

- Disconnected neg terminal at battery

- Completed electrical connections in passenger compartment

- TESTED SYSTEM TO MAKE SURE IT WORKS:

- (Connected MCD to harness. Used alligator clips to connect MCD threaded portion to ground. Put negative battery lug back on terminal, didn't tighten. Put key in, turned to ON. IMS-G amber light on; pushed switch, light went red, alarm sounded. Disconnected battery again, unhooked MCD from harness.)

(My logic: why drain the oil BEFORE checking if the system works???)

- Drained oil and removed filter

- Removed sump plate, cleaned

- Installed MCD, hand tightened in sump plate

- Reinstalled sump plate with Loctite 5900, torqued sump plate and MCD to specs. NOTE: MCD should be torqued to 19 ft. lbs.

- Connect MCD to wire harness, tidied up wiring

- Installed new filter, torqued filter housing to spec

- Filled with oil

- Reconnected battery, checked system again

- Reinstalled plastic shield

- Started engine, checked for leaks, checked oil level

- Reinstalled firewall carpeting

For me, and your mileage may vary, this was the right way to approach the job. I suppose if you're experienced with wiring and feeding wires through/around a car's dash, you would have breezed through the wiring process. Me? I took it very slowly, and actually drove the car around town for a week or so with the wiring in the dash in place, but not yet connected.

A observations, photos, and tips...

Actually feeding the wire through the dash wasn't difficult,

but it could have been. After trying to fish the wires around the HVAC and radio units a few times without success, I had the idea of using a piece of twist tie-type material that was about two to three feet long. I formed it into a circle with a radius of about 3 inches, and then fed it from one side of the center stack to the other; here you can easily see both ends:

I then taped the 2 wires which need to go from one side to the other to the twist tie material, and fed the wires through. You can see the electrical tape securing the wires to the twist tie material in the circle to the right:

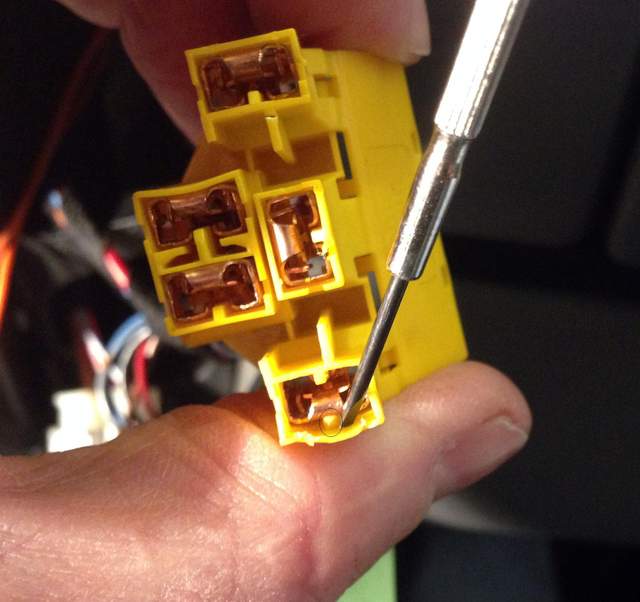

Oh - another thing: the instructions and the IMS-G video show how to remove the wire at #3 in the connector you're to attach the two wires to. Uh, how can I put this? What's shown in the video bears no relationship to reality, at least as regards to the connectors in my car. You have to really examine the spade-type connectors and figure out how they're held in place. In my case, I had to pry the connector up and off a small plastic tab from the FRONT of the connector:

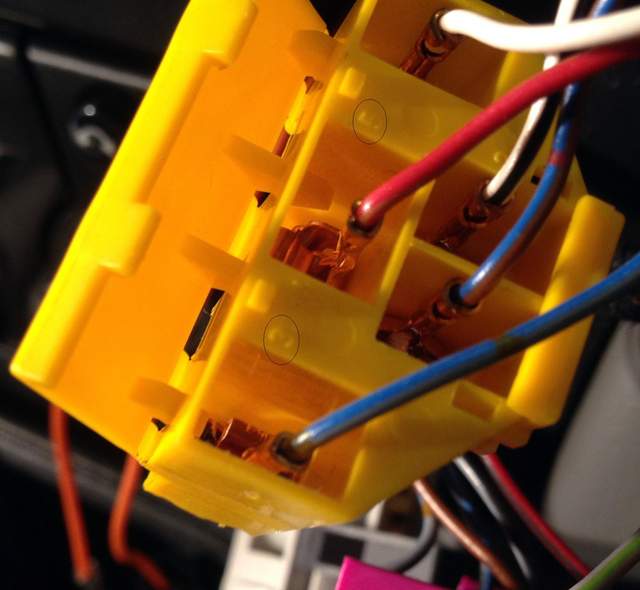

Incidentally, I read somewhere on the interwebs that the wires are not numbered in the connectors. This is not true. See below; #'s 3 & 5 are circled. (Edit: this was on my car; see Jake's comment below)...

I have to thank Pedro for his help with the install of the wire through the firewall. I tried a few times, but ya gotta be some sort of contortionist/David Blaine-type to feed the wire from the passenger compartment through to the engine compartment. For whatever reason, I struggled with it

a lot. Pedro suggested (and provided helpful photos; THANKS!) that I simply punch a hole through the firewall. The best tool for this job is a knockout punch. Thanks to a wonderful mixture of stubbornness and stupidity, I tried to use a 1" drill bit instead. The flutes on that bit are so big that it grabbed and tore the firewall a bit. We ground out the rough edges, and I installed a grommet and used high temp Permatex silicone to provide a seal:

That's a hemostat holding the wire in the center of the grommet, by the way. (Forty years ago, I would have referred to the hemostat as a roach clip. Ha! I'm old!)

The plastic shield beneath the engine, at least in my opinion, needs to be removed in order for you to be able to easily locate the wire in the engine compartment, and for ease in reinstalling the sump plate. No biggie; it was an opportunity to clean it and treat it with some 303 protectant. I am NOT obsessive compulsive!!!!

If you've looked at the IMS-G instructions, you've undoubtedly noted that you can't torque the MCD (the Magnetic Chip Detector, aka your new drain plug with wires sticking out the side) unless you have a special socket. I couldn't find it at the LN Engineering site, and Pelican doesn't carry it, as far as I could determine. So I took a 26mm socket to the guy who runs our Tool Room at work, and he milled a slot in it with a Bridgeport milling machine (the slot is deeper than it needs to be, my bad):

The socket worked absolutely great. Cost? What else? A dozen donuts.

One thing I didn't bother taking a picture of: to keep the wiring in the fuse box neat, I used one of those hobbyist-type glue guns to locate the wire. It keeps the wire away from the tabs on the cover, a good thing.

Wrapping up...

All in all, I'm happy with the install and the kit itself.

The components are clearly of high quality. The instructions could benefit from a little attention by a professional tech writer. Failing that, I'd suggest someone who's never done the job do it at Jake's shop, and whoever's responsible for the instructions watch carefully and take notes. My understanding is that the instructions have been upgraded, and as mentioned in another post, I didn't receive the latest version when I ordered from Pelican - hopefully the instructions addressed some of the points mentioned here.

The alarm isn't particularly loud, but knowing myself, I'll glance at the indicator light once in a while. The IMS-G will provide some real peace of mind until I do the bearing retrofit at some point in the future.

Hope this helps someone else!