Quote:

Originally Posted by blue2000s

I'm using Fluent in these simulations.

A Y will be more efficient than a T for airflow in a steady state, that's correct.

Keep in mind that with three cylinders to a plenum, there is a pretty much constant flow of air into the plenum when the engine is kept at a constant speed. There is always a cylinder pulling air. The pulses that influence secondary pressure waves are important, but they are secondary in nature so the influence on flow is on a much lower order than the primary vacuum pulled by the cylinders themselves.

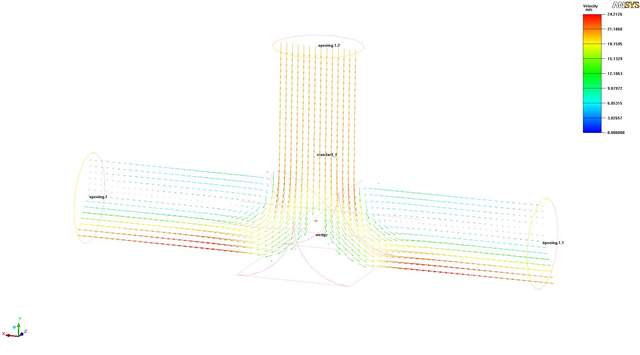

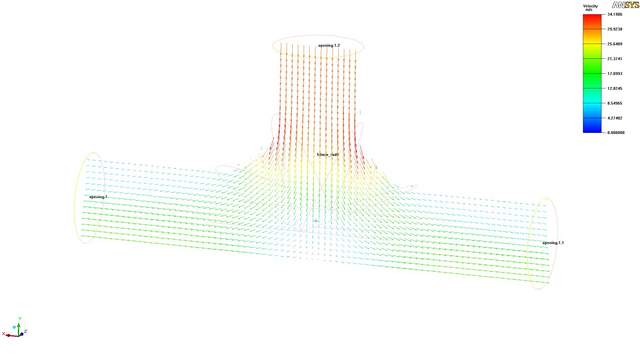

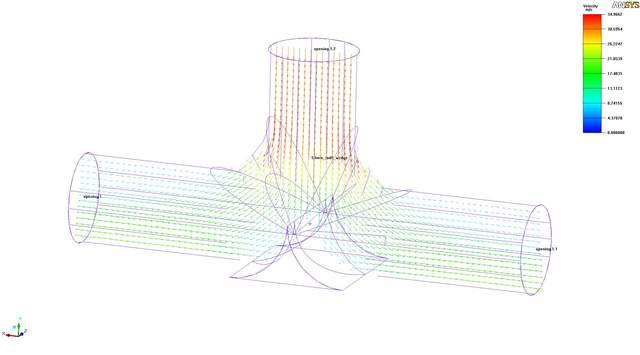

Here are three more simulations varying on the one I posted earlier. The first one just adds a sloped wedge to the original T. The second adds a large radius to the T junction and the last one combines the radius with the wedge.

The volume flow rate results show that the T and T with wedge have almost identical flow rates. The radius-ed T with and without the wedge are both almost the same flow rates but are about 30% greater than the standard T. |

Well done; well put. I was just considering any tendency to pull from bank to bank when the firing order is such that there is a strong intake pull from one side versus the other.

Looks like in theory the 'y' has some definite benefits...now comes the hard part part of testing varying shapes and geometries.