03-09-2013, 07:01 AM

03-09-2013, 07:01 AM

|

#1

|

|

Registered User

Join Date: Dec 2010

Location: Eastern canada

Posts: 262

|

Engine Rebuild Balancing

I have read through different forums and postings on this rebuild topic and every now and again someone mentions "balancing" in the rebuild process, what are they referring to?

What needs to be balanced? If you put back what you took out or machine equally if that is the case should things not be balanced?

Any info on this topic would be good.

Last edited by pjq; 03-09-2013 at 08:43 AM.

|

|

|

03-09-2013, 07:05 AM

03-09-2013, 07:05 AM

|

#2

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Anything is balanced if your tolerance of acceptance is wide enough. These engines are dynamically balanced very poorly from the factory; they just installed a 37 pound dual mass flywheel to smooth it out. The accountants said it was cheaper that way.

Study dynamic balancing and understand it before you can truly see how and why it is important to any engine.

Dynamic balancing and harmonics associated with a lack of it can even effect your ignition timing at upper RPM ranges with the M96 engine. Sounds crazy.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

03-09-2013, 07:14 AM

03-09-2013, 07:14 AM

|

#3

|

|

Registered User

Join Date: Dec 2010

Location: Eastern canada

Posts: 262

|

[QUOTE=Jake Raby;330736]Anything is balanced if your tolerance of acceptance is wide enough. These engines are dynamically balanced very poorly from the factory; they just installed a 37 pound dual mass flywheel to smooth it out. The accountants said it was cheaper that way.

Jake, I always enjoy your sarcastic comments!! haaaaa!

So, how is the balancing of these engines carried out, are weights added or shims used? I understand the precession of placing things back where they came from with the allowable tolerances but what actually is being balanced the crankshaft, pistons, camshafts??

|

|

|

03-09-2013, 10:06 AM

03-09-2013, 10:06 AM

|

#4

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

So, how is the balancing of these engines carried out, are weights added or shims used? I understand the precession of placing things back where they came from with the allowable tolerances but what actually is being balanced the crankshaft, pistons, camshafts??[/QUOTE]

Ideally most balancing can be accomplished by removing material from a heavy area to match the lighter areas. With pistons & rods each part is weighed individually to find the lightest part & then material is machined off to lighten the part until it weighs the same as the lightest part. With M96 engines the only part I have had to add weight is the pressure plate since there are few places to remove weight. Seems to me the flywheel & pressure plate are the biggest source of imbalance.

|

|

|

03-09-2013, 10:50 AM

03-09-2013, 10:50 AM

|

#5

|

|

Registered User

Join Date: Mar 2013

Location: Cary, NC

Posts: 35

|

Quote:

Originally Posted by Jake Raby

Anything is balanced if your tolerance of acceptance is wide enough. These engines are dynamically balanced very poorly from the factory; they just installed a 37 pound dual mass flywheel to smooth it out. The accountants said it was cheaper that way.

Study dynamic balancing and understand it before you can truly see how and why it is important to any engine.

Dynamic balancing and harmonics associated with a lack of it can even effect your ignition timing at upper RPM ranges with the M96 engine. Sounds crazy.

|

Thats why you were such a HUGE advocate of the aluminum standard flywheel UPGRADE in WTI training at Orlando.  Removal of the only factory vibration dampening capabilities is always a good idea.

|

|

|

03-10-2013, 06:05 AM

03-10-2013, 06:05 AM

|

#6

|

|

Registered User

Join Date: Dec 2010

Location: Eastern canada

Posts: 262

|

If the home DIY'r is able to reassemble the engine to factory tolerences, get the weights correct on the crankshaft connections and then manually turn the crank and it feels smooth and rotates easily how do we know if we truley got it exact, because I'm getting the idea these Engines are suppose to be exact.

At a engine rebuild shop do they have machines to check themselves as they go?

What about when you finally bring the engine up to 6 -7000rpm and it must be smooth, do rebuild shops have machines for this or is it the experience of the builder?

Since balance is so important how can we replace our own clutch assembly and not mess up the fine balance, surely there is slight weight variations in the new parts? From what I read and see you take off the old flywheel, disk, plate and bolt on the new, there is no rebalancing happening at this stage?

Any thoughts?

|

|

|

03-11-2013, 11:09 AM

03-11-2013, 11:09 AM

|

#7

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by pjq

If the home DIY'r is able to reassemble the engine to factory tolerences, get the weights correct on the crankshaft connections and then manually turn the crank and it feels smooth and rotates easily how do we know if we truley got it exact, because I'm getting the idea these Engines are suppose to be exact.

At a engine rebuild shop do they have machines to check themselves as they go?

What about when you finally bring the engine up to 6 -7000rpm and it must be smooth, do rebuild shops have machines for this or is it the experience of the builder?

Since balance is so important how can we replace our own clutch assembly and not mess up the fine balance, surely there is slight weight variations in the new parts? From what I read and see you take off the old flywheel, disk, plate and bolt on the new, there is no rebalancing happening at this stage?

Any thoughts?

|

It's more about preparation of the parts before you begin assembly. Insure every part you are putting into the engine is up to the task you are assigning it. (Daily driver for another 150K miles + autocrossing, or 30 minute lap sessions on track, or 24 hours of Daytona race.) The engine is only as strong as the weakest link. (part)

Find the best engine balancer you can send the reciprocating assembly to: Front crank pulley,bolt & washer, crankshaft, rods & bolts, pistons & pins & circlips, new flywheel & pressure plate, consider sending a 2nd flywheel & pressure plate since most balancing shops can't balance the flywheel & pressure plate without a crankshaft to mount on.

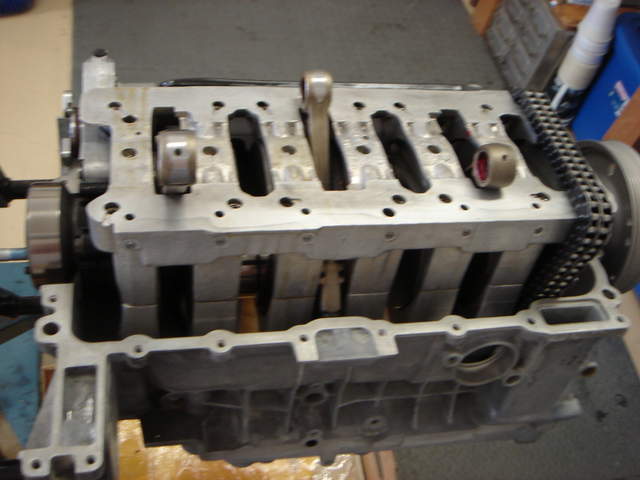

Usually very little material is added or removed as seen on the rods in the picture below.

|

|

|

03-12-2013, 05:36 AM

03-12-2013, 05:36 AM

|

#8

|

|

Registered User

Join Date: Dec 2010

Location: Eastern canada

Posts: 262

|

To keep this topic in perspective, when these engines are new off the line how well balanced are they?

I thought Jakes statement below was just humorous sarcasism with a touch of exaggeration but is it really that way?

"These engines are dynamically balanced very poorly from the factory; they just installed a 37 pound dual mass flywheel to smooth it out. The accountants said it was cheaper that way."

If so that means there is alot of room for improvement on the stock engine, without resizing.

|

|

|

03-10-2013, 08:02 AM

03-10-2013, 08:02 AM

|

#9

|

|

Certified Boxster Addict

Join Date: Nov 2010

Location: Los Angeles

Posts: 7,669

|

Its all about tolerances.

Replacing the clutch and flywheel with OEM parts is generally an accepted practice - that is why the dual mass flywheel is there, to mitigate (to an acceptable tolerance according to Porsche) the imbalance imparted by the original parts and any change in balance as they wear and any changes from the new replacement parts.

If you have the time and the means, you can statically weigh/balance the new clutch parts. If you have more time and money you can dynamically balance the new clutch parts. Its the same idea as balancing your wheels/tires.

Its the same with engine rebuilding. You can do a DIY job and not balance anything. Or you can have a machine shop weight match some components. Or you can weigh and balance everything.

__________________

1999 996 C2 - sold - bought back - sold for more

1997 Spec Boxster BSR #254

1979 911 SC

POC Licensed DE/TT Instructor

Last edited by thstone; 03-10-2013 at 08:04 AM.

|

|

|

03-10-2013, 09:39 AM

03-10-2013, 09:39 AM

|

#10

|

|

Registered User

Join Date: Dec 2010

Location: Eastern canada

Posts: 262

|

Well considering the Engine is the Heart of a porsche, i think this topic of "balance" is the BEAT of the Engine.

I need to start disassembling and washing this engine see what I have or more practical what I wish I didn't have, as I do I'll think more about engine balance.

I'm starting to think its the road to perfection.

Any more info on this subject would be great.

Last edited by pjq; 03-10-2013 at 02:51 PM.

|

|

|

03-10-2013, 12:54 PM

03-10-2013, 12:54 PM

|

#11

|

|

Track rat

Join Date: Nov 2006

Location: Southern ID

Posts: 3,701

|

As a rule of thumb, the better balanced an engine throughout all moving parts, the greater it's reliability under stress or high revs. An F1 motor is insanely well balanced. A well balanced engine also makes more power.

__________________

2009 Cayman 2.9L PDK (with a few tweaks)

PCA-GPX Chief Driving Instructor-Ret.

Last edited by Topless; 03-10-2013 at 12:56 PM.

|

|

|

03-10-2013, 05:59 PM

03-10-2013, 05:59 PM

|

#12

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

.

Quote:

|

What about when you finally bring the engine up to 6 -7000rpm and it must be smooth, do rebuild shops have machines for this or is it the experience of the builder?

|

Those of us who have invested in the business enough to do EVERYTHING associated with an engine reconstruction/ update under one roof have balance machines. I learned over a decade ago that I couldn't "farm out" balance work and ever have my tolerances met.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

Last edited by Jake Raby; 03-10-2013 at 06:10 PM.

|

|

|

03-10-2013, 06:09 PM

03-10-2013, 06:09 PM

|

#13

|

|

Registered User

Join Date: Nov 2012

Location: Southern, CA

Posts: 460

|

One other item that has not been discussed is a very well balanced engine can also have s higher safe RPM range. I don't know enough about the boxster engine but suspect if it is properly balanced and the proper upgrades are made to the valve train you could exceed the current RPMlimits if the DME were reprogrammed. I could be wrong though.

On prior cars and particularly motorcycles though a precision balance has raised horsepower, torque, and RPM. If I were to rebuild my engine I would get it professionally balanced.

__________________

1999 Boxster Zenith Blue Metallic/Savanna Beige

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 12:48 AM.

| |